Our Machining Projects

Why Choose Us?

-Custom parts from your drawings, no MOQ.

-End-to-end service: sourcing, machining, finishing & QC.

-Streamlined process = on-time delivery, every time.

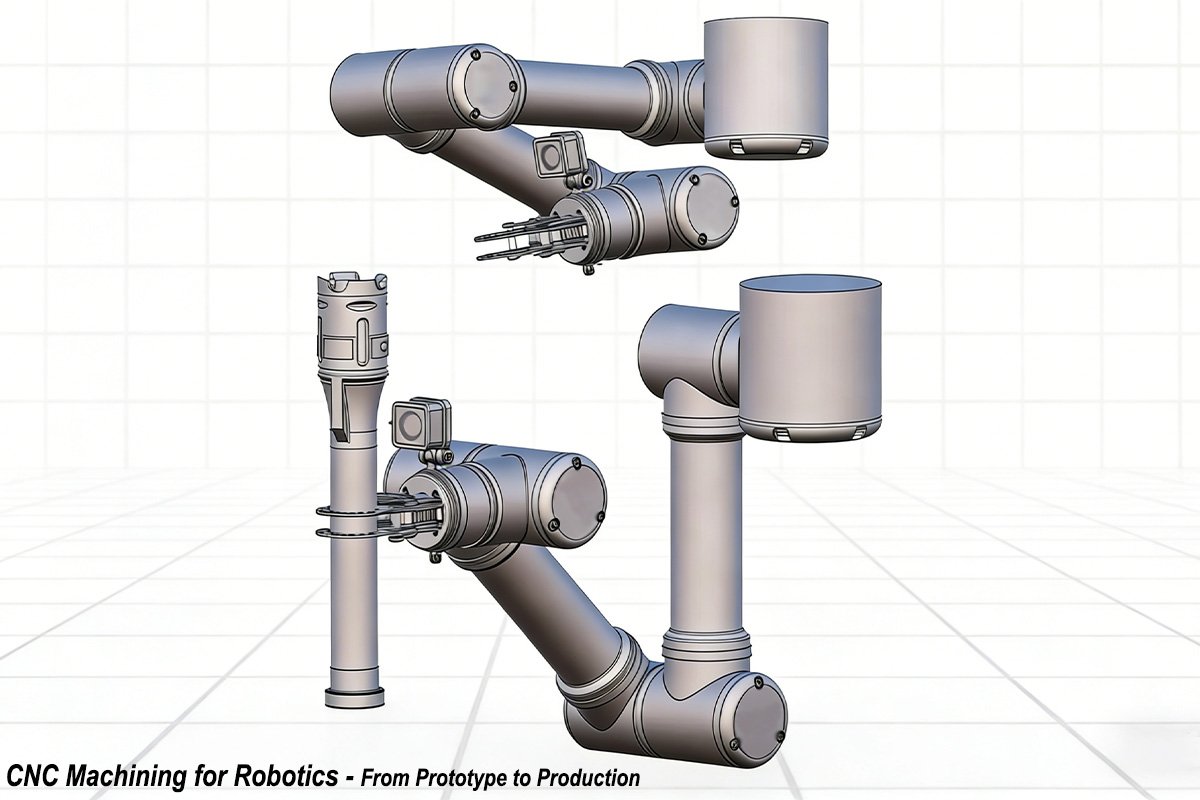

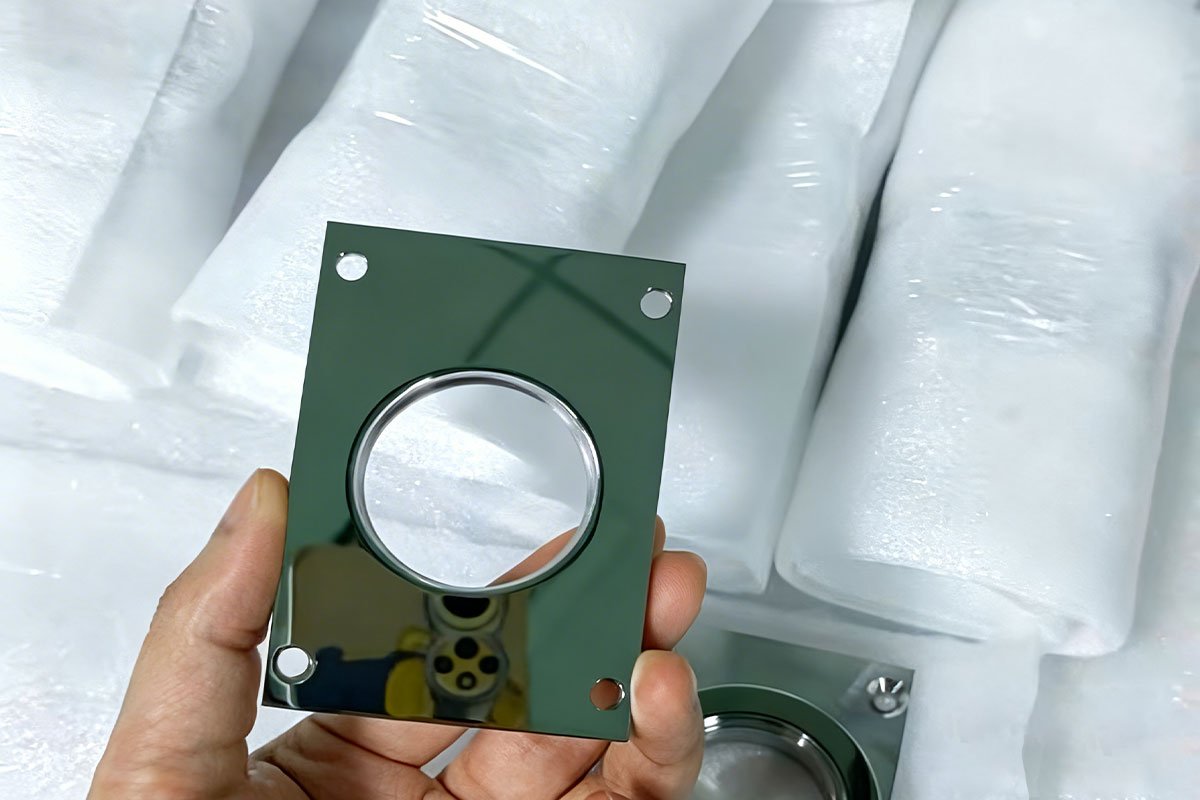

CNC Machining Aluminum 7075 Gimbal Arm for Drone Camera Stabilizers

The component shown is a lightweight aluminum 7075 CNC machined gimbal arm for a 3-axis drone gimbal system. The component shown is a lightweight aluminum 7075 gimbal arm for a 3-axis drone gimbal system. To reduce rotational inertia, the design features a complex curved profile with extensive material removal (pocketing). The manufacturing objective was to achieve a high stiffness-to-weight ratio while maintaining tight tolerances on the bearing bores to ensure precise camera stabilization.

Project Details

Part type: Gimbal Arm

Material: Aluminum 7075-T6

Critical Tolerance: ±0.05mm

Quantity: 100 pcs

Lead Time: 15 day

Manufacturing Process Details

Due to the component’s curved geometry and undercut features, a 5-axis CNC machining center was utilized. This setup allowed for continuous tool access to the complex outer profile and the internal cable routing channels without multiple re-fixturing steps, ensuring better geometric alignment between the mounting base and the motor housing.

Following the milling process, a fine boring operation was conducted to achieve the specified tolerance. This ensures a precise interference fit for the gimbal motor.

Free Quote & Design Review

We provide custom CNC machining services for low-volume production and Rapid Prototyping for design verification. Click Here to Upload Your CAD Files

Our Manufacturing Capabilities

Capabilities include 3-Axis, 4-Axis, and 5-Axis CNC Milling, as well as CNC Turning operations. Standard materials processed include Aluminum alloys, Stainless Steel, Titanium, etc. and Engineering Plastics. Available secondary operations include Anodizing, Powder Coating, Bead Blasting, and Laser Engraving.

Capacity supports requirements ranging from single-unit Rapid Prototyping to Low-Volume Production runs (1-1,000+ units).

Factory Quality Assurance

A standardized Quality Management System (QMS) is applied to all manufacturing orders, regardless of part complexity or production volume. The following inspection stages are mandatory for every CNC machining project:

Order Fulfillment Process

From CAD to part.

FAQs About CNC Machining Services

Latest articles

March 3, 2026