How We Achieve High-Gloss Parts with Acrylic CNC Machining

Acrylic (PMMA) is a beloved material for custom CNC machined parts, celebrated for its crystal-clear transparency, sleek high-gloss appearance, and versatility across industries—from signage, electronics enclosures, and automotive interiors to consumer products and precision instruments.

However, many manufacturers struggle with a common frustration: even after CNC machining, acrylic parts often lack consistent high transparency and gloss, requiring time-consuming, costly extra surface treatments (like polishing or buffing) to achieve the desired finish.

At our custom CNC machining service, we’ve solved this pain point for our clients. The secret? Our CNC-machined high-gloss acrylic parts come with high transparency and a gloss finish right off the machine—no extra surface treatment needed. This is made possible by our combination of custom specialized tools and optimized machining processes, tailored specifically for acrylic’s unique properties. In this guide, we’ll break down how we achieve ready-to-use high-gloss, high-transparency acrylic parts, the key challenges we overcome, and why our approach saves you time, money, and hassle.

Why Most CNC Machined Acrylic Parts Lack High Transparency

To understand our difference, it’s first important to know why standard CNC machining often fails to deliver high transparency and gloss for acrylic parts—forcing extra surface treatment. Acrylic’s inherent properties create three key hurdles that most machinists struggle to overcome:

- Surface Scratches & Fogging: Acrylic is soft and scratch-prone; standard tools or improper chip evacuation leave tiny scratches or cause slight melting (from excess heat), resulting in a foggy, dull surface that blocks light transmission.

- Edge Chipping & Roughness: Acrylic’s brittleness leads to edge chipping during machining with generic tools. Rough, chipped edges scatter light, reducing overall transparency and ruining the high-gloss look—requiring manual polishing to fix.

- Uneven Cutting & Stress: Generic tools and unoptimized processes create uneven cutting forces, leaving surface irregularities that disrupt light transmission. These flaws can only be corrected with extra surface treatment.

The solution isn’t more post-processing—it’s better machining from the start.

CNC Machining High-Gloss, High-Transparency Acrylic Parts (No Extra Treatment Needed)

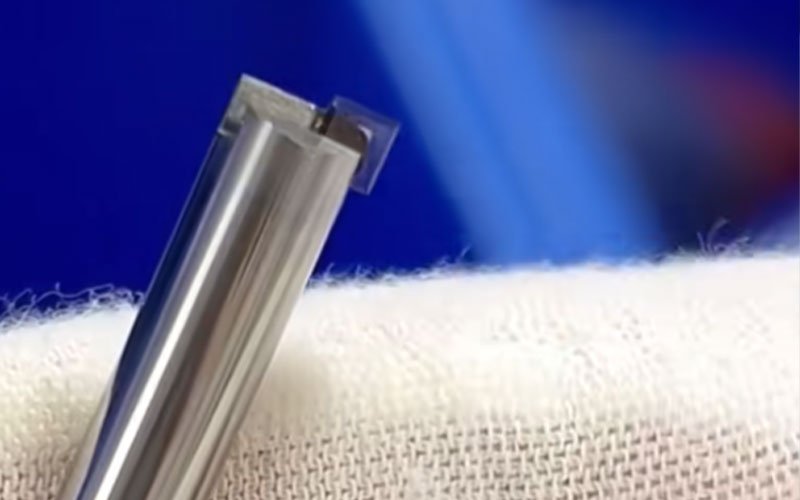

1. Custom Monocrystalline Diamond (MCD) Tools

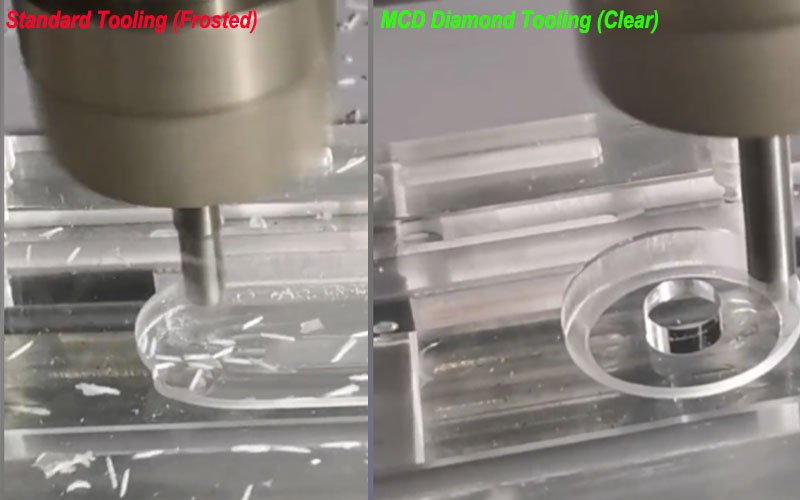

Surface finish comparison using different tooling. Left: Result from a standard carbide end mill. Right: Result from a Monocrystalline Diamond (MCD) tool.

First, let’s introduce our monocrystalline diamond (MCD) tools in detail: MCD tools are ultra-precision cutting tools made from synthetic diamond raw materials. They feature outstanding properties including a microhardness of 10000HV and a friction coefficient of 0.05-0.07, with an edge radius as small as 0.002μm. These tools can machine non-ferrous metals and composite materials with a surface roughness of Rz0.05~0.1μm.

The pristine cutting edge of an MCD tool is essential for achieving optical clarity directly from the CNC machine, eliminating the need for hand polishing.

Unlike generic tools or even standard carbide tools that leave flaws requiring extra polishing, our custom MCD tools deliver a mirror-like high-gloss and high-transparency surface right from the cut—eliminating the need for any post-processing.

2. High-Precision 5-Axis CNC Machining

Utilizing 5-axis CNC technology to machine complex curved surfaces on acrylic without the need for multiple re-fixturing.

We use high-precision 5-axis CNC machines, which work seamlessly with our diamond tools to achieve unparalleled cutting accuracy—another key to delivering high-transparency, high-gloss acrylic parts without extra treatment.

- Exceptional Machining Accuracy: With ultra-high positioning accuracy and repeatability, our 5-axis CNC machines ensure every cut is consistent and precise. This eliminates uneven cutting forces and surface irregularities that disrupt light transmission, working in tandem with our single-crystal diamond tools to create a perfectly smooth, scratch-free surface.

- Multi-Angle One-Time Machining: Unlike 3-axis machines that require multiple setups for complex or curved acrylic parts (increasing the risk of scratches and misalignment), our 5-axis machines can machine all surfaces and angles in one setup. This minimizes part handling, reduces the chance of surface damage, and ensures seamless, uniform gloss across the entire part—even for intricate or 3D curved designs.

3. Optimized Machining Process

Even the best tools need a proper strategy. Our optimized CNC machining process is designed to minimize heat, reduce cutting force, and ensure smooth chip evacuation—all critical to preserving acrylic’s high transparency and gloss.

4. Gentle Post-Machining Care (No Extra Treatment—Just Protection)

Since our machining delivers a perfect finish, we only perform minimal post-processing—focused on protection, not correction:

- Non-Abrasive Deburring: We use soft, plastic scrapers to remove tiny burrs (if any) without scratching the surface. No sanding or buffing is needed—our cuts are clean enough to skip these steps.

- Acrylic-Safe Cleaning: We clean parts with a mild, residue-free cleaner to remove any dust or coolant—restoring maximum transparency and gloss without damaging the surface.

- Protective Packaging: We keep the protective film on until delivery and package parts in scratch-resistant materials to ensure they arrive in perfect condition—ready for assembly.

Common Acrylic Post‑Processing Methods

Manual Wet Sanding

Sand progressively from 400 grit up to 2000 grit for a smooth surface.

- Disadvantages: Time‑consuming, highly dependent on manual experience.

Buffing

Used with polishing compound to achieve high gloss.

- Advantages: High surface gloss.

- Disadvantages: Difficult to finish complex internal corners.

Flame Polishing

Fast and effective for clear surfaces.

- Advantages: High processing speed.

- Disadvantages: Risk of stress crazing, yellowing over time, not suitable for high‑precision parts.

Vapor Polishing

Uses solvent vapor to smooth acrylic surfaces automatically.

Why “As-Machined” is Better than “Polished” for High-Gloss Acrylic Parts

Many manufacturers assume that polishing is the only way to achieve a high-gloss, high-transparency finish for acrylic parts. However, when done correctly—with custom single-crystal diamond tools and high-precision 5-axis CNC machines—our as-machined finish (parts straight off the machine, no extra polishing) is not just equal to polished parts, but superior in quality, consistency, and cost-effectiveness. Here’s why:

No Risk of Surface Damage from Polishing

Polishing (whether manual or automated) involves abrasive materials that can scratch, haze, or distort the acrylic surface. Even careful polishing can leave micro-scratches or uneven areas that disrupt light transmission—undermining the “high-transparency” goal. Our as-machined finish avoids this entirely: the custom single-crystal diamond tools and 5-axis precision machining create a flawlessly smooth surface without any abrasive contact.

Superior Light Transmission & Gloss Uniformity

Polishing often creates uneven gloss across the part, especially on intricate or curved designs, as it’s difficult to apply consistent pressure and abrasion. Our as-machined finish, by contrast, uses controlled, precise cutting with ultra-sharp diamond tools and stable 5-axis machines—ensuring uniform gloss and crystal-clear transparency across every inch of the part. The surface remains true to acrylic’s inherent clarity, with no haze or distortion.

Time & Cost Savings (No Extra Labor or Materials)

Polishing is a time-consuming, labor-intensive step that adds significant cost to your project—requiring extra materials (abrasives, polishes) and extended lead times. Our as-machined parts are ready for use immediately after machining, eliminating polishing costs and cutting turnaround time by 20–40%. This means you get your parts faster and at a lower cost, without sacrificing quality.

No Compromise on Part Precision

Polishing can remove small amounts of material, altering the part’s dimensions and precision—critical for custom acrylic components used in electronics, instruments, or tight assemblies. Our as-machined finish maintains the exact dimensions of your design, as we achieve the perfect surface during cutting, not through post-processing. This ensures a precise fit and consistent performance every time.

The bottom line: Polishing is a “fix” for poor machining. When start with the right tools (custom single-crystal diamond), the right equipment (high-precision 5-axis CNC machines), and an optimized process, as-machined acrylic parts are better—more consistent, more precise, more cost-effective, and just as glossy and transparent as polished alternatives.

Common Applications of High-Gloss, High-Transparency Acrylic Parts

High-gloss, high-transparency acrylic is widely used across industries where clarity, precision, and aesthetics matter most. Our custom CNC machining process—powered by synthetic single-crystal diamond tools and high-precision 5-axis machines—delivers flawless as-machined acrylic parts that excel in these critical applications, with no extra surface treatment needed:

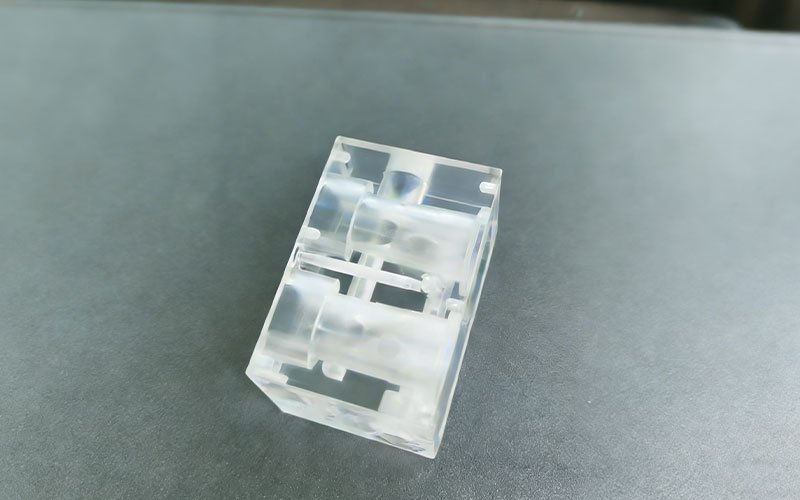

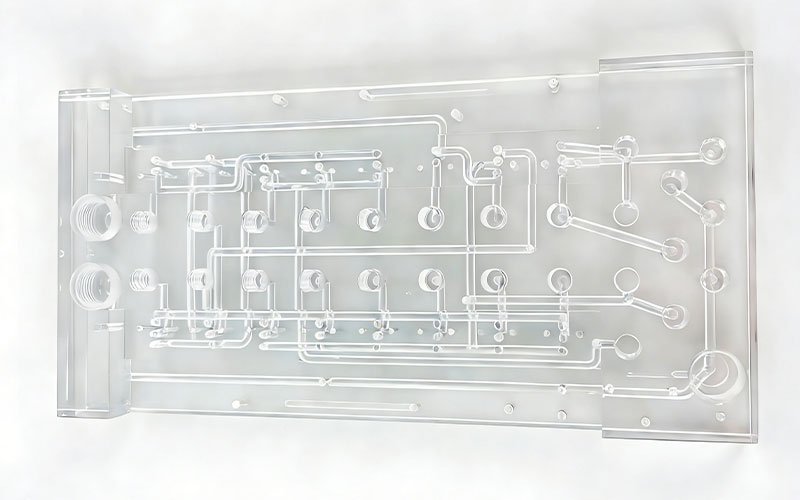

Acrylic Complex Manifolds

Used in fluid handling, medical devices, and industrial equipment, acrylic complex manifolds require exceptional transparency to monitor fluid flow and purity.

Lenses & Light Guides

Acrylic lenses and light guides are essential in optics, automotive lighting, electronics, and signage. These components demand ultra-high transparency and uniform gloss to ensure consistent light transmission and distribution.

Instrumentation Covers

Used to protect dials, displays, and sensitive instruments in medical, aerospace, and industrial settings, instrumentation covers need both high transparency (for easy readability) and durability.

No matter your application, our process ensures your high-gloss acrylic parts meet the strictest clarity, precision, and aesthetic requirements—saving you time and cost without compromising on performance.

Get High-Gloss, High-Transparency Acrylic Parts

If you are frustrated with dull, foggy acrylic parts that require extra surface treatment, we can help. Send us your part drawing (CAD files are accepted), and our team will design a custom CNC machining plan—using our specialized tools and optimized processes—to produce high-transparent, high-gloss acrylic parts that are ready for use right away. Contact us today for a free quote.

Share this article

Written by : Alex

A quick overview of the topics covered in this article.

Latest articles

February 20, 2026

February 20, 2026

February 20, 2026