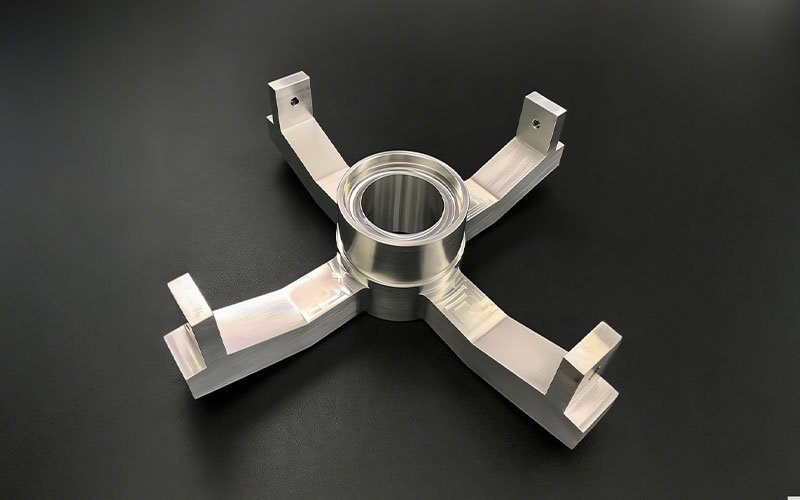

Custom Aluminum CNC Machining Services

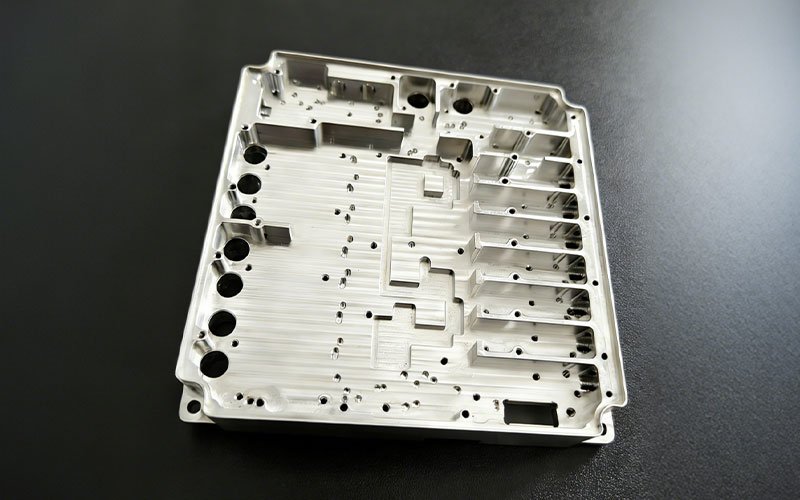

From rapid prototyping to low-volume production. We utilize high-speed CNC centers optimized for aluminum processing. We support a wide range of alloys and provide full-service post-processing, including anodizing, bead blasting, and chromate conversion. Whether you are designing complex aerospace brackets or cosmetic electronic enclosures, our team ensures your parts meet strict ISO 9001 standards.

Aluminum is the most versatile material in manufacturing, favored for its excellent strength-to-weight ratio and machinability. However, achieving tight tolerances and distortion-free parts requires specific expertise.

Available Aluminum Grades for Machining

We stock a wide variety of aerospace and commercial-grade aluminum alloys to meet your specific project requirements.

Aluminum 6061-T6

Aluminum 6061-T6 is the most widely utilized alloy in CNC machining, valued for its exceptional balance of mechanical strength, corrosion resistance, and workability. This precipitation-hardened grade exhibits excellent machinability, allowing for high cutting speeds, and unlike the 7000 series, it is readily weldable via TIG or MIG methods.

Additionally, 6061 is the preferred choice for post-processing; it accepts Type II and Type III anodizing exceptionally well, ensuring uniform cosmetic finishes and protective hard coatings, as well as conductive chemical conversion films.

Common Applications:

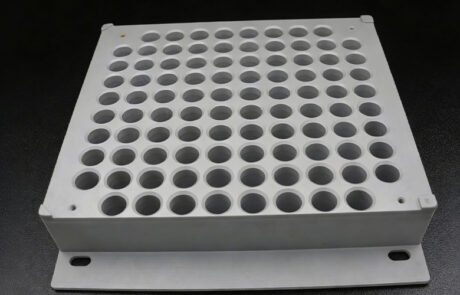

- Electronics: Custom enclosures, heat sinks, and mounting brackets.

- Automotive: Valve bodies, brake components, and suspension parts.

- Structural: Base plates, frames, and machine fixtures.

- Consumer Products: Camera bodies and durable equipment housings.

Aluminum 6063

Aluminum 6063 for applications where surface finish and aesthetic quality are paramount. While it possesses lower tensile strength than 6061-T6, it offers superior corrosion resistance and an exceptional response to anodizing. This alloy produces a smoother, more uniform surface layer, making it the preferred material for manufacturing high-end mechanical keyboard cases, electronic enclosures, and thermal management components like heat sinks.

Common Applications:

- Thermal Management: Custom heat sinks, cooling fins, and LED lighting housings (due to high thermal conductivity).

- Consumer Electronics: Device enclosures and bezels where cosmetic anodizing quality is prioritized over structural strength.

- Extrusion Post-Machining: Drilling, tapping, and milling features into standard extruded tubing or profiles.

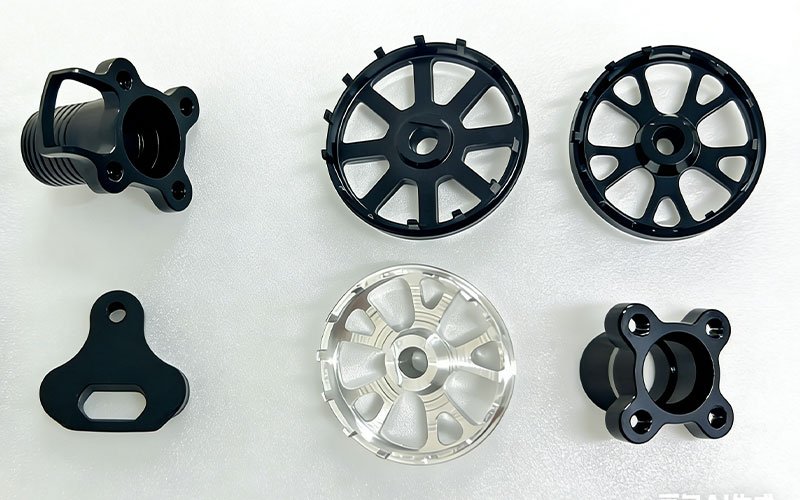

Aluminum 7075-T6

Aluminum 7075-T6 is one of the highest-strength aluminum alloys available, with zinc acting as the primary alloying element. It offers a strength-to-weight ratio comparable to many low-carbon steels while retaining the lightweight properties of aluminum. While 7075 exhibits fair machinability and excellent fatigue resistance, it has lower corrosion resistance than the 6000 series and is not recommended for welding due to the risk of stress-corrosion cracking.

Common Applications:

- Aerospace & Defense: Aircraft wing spars, fuselage bulkheads, and tactical scope mounts requiring high tensile strength comparable to steel.

- Automotive & Motorsport: Suspension control arms, billet brake calipers, and wheel hubs designed to reduce unsprung weight and resist fatigue.

- Robotics & Automation: Lightweight robotic arms, end-effectors, and precision gears where minimizing inertia is critical for high-speed performance.

Surface Finishing Options for Aluminum Parts

Improve part performance and appearance. We offer a wide range of finishes to ensure wear resistance and corrosion protection. Explore our mechanical and chemical options below.

As-machined

Anodizing

Bead Blasting

Powder Coating & Wet Painting

Part Marking

FAQs About CNC Machining Services