Our Machining Projects

Why Choose Us?

-Custom parts from your drawings, no MOQ.

-End-to-end service: sourcing, machining, finishing & QC.

-Streamlined process = on-time delivery, every time.

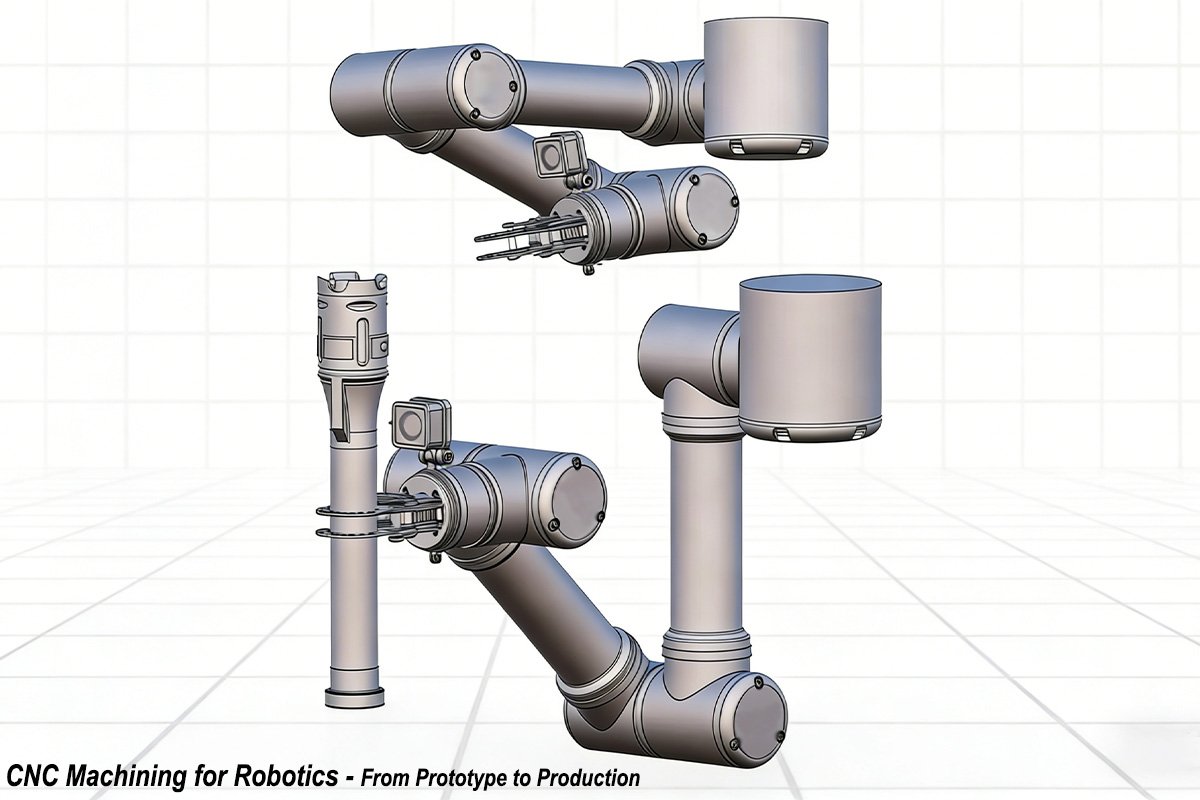

Custom CNC Machining Robot Joint Housing

How to balance lightweight design with high durability? This was the challenge when a robotics startup approached us to manufacture a custom robot joint housing. The part required Aluminum 7075 for strength but featured complex thin walls that demanded expert CNC machining strategies. In this project, our solution for custom CNC machining robot joint housing focused on controlling internal stress and ensuring concentricity, proving that we can deliver reliable parts even for the most complex humanoid robots.

Project Details

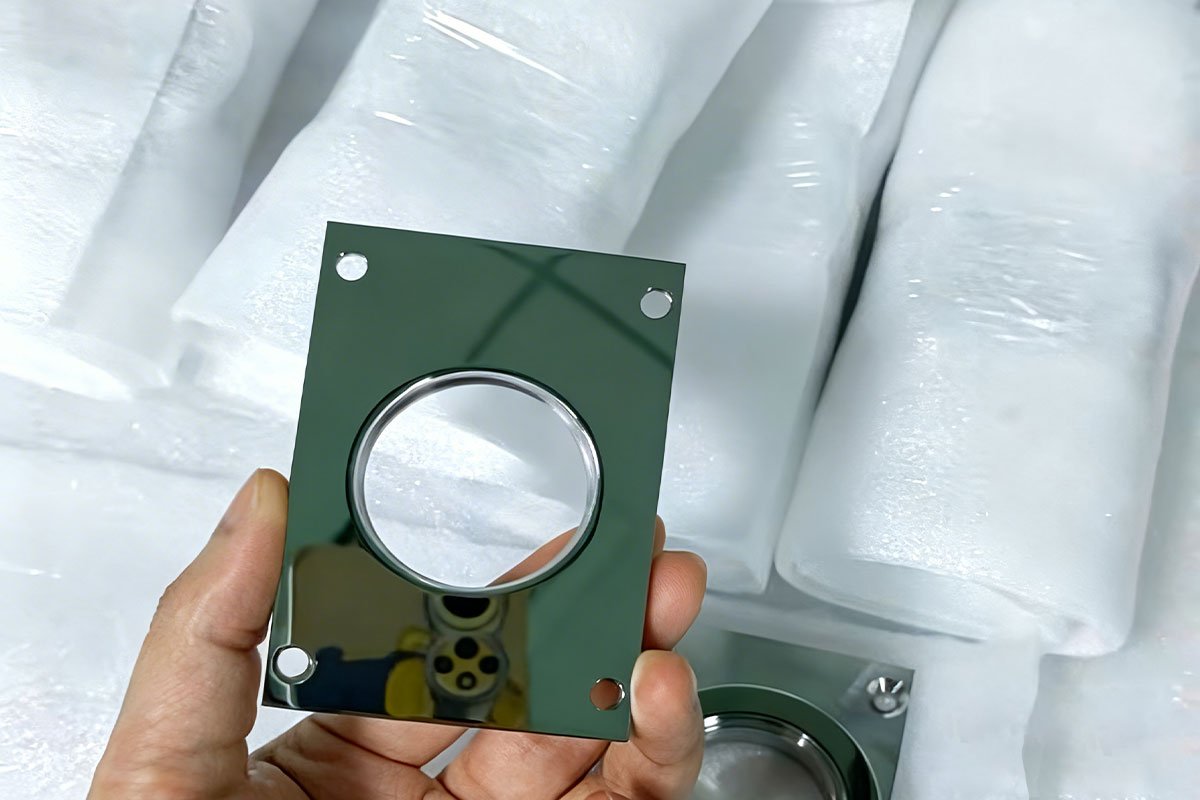

Part type: Robot Joint Housing/Casing/Shell

Material: Aluminum 7075

Key Tolerance: 0 / +0.02 mm

Concentricity: ≤ 0.015 mm

Quantity: 20 pcs

Quality Control: CMM Inspection, 100% Full Dimension Check

Lead Time: 15 day

Our Manufacturing Solution

To ensure the highest precision for this thin-walled part, we implemented a strict multi-stage process. We began with rough machining, leaving a 0.5mm allowance, and allowed the parts to settle for 24 hours to fully release the internal stress of the material.

To prevent deformation during finishing, we designed a custom internal expansion fixture (ID Clamp) to hold the part from the inside, distributing the clamping force evenly. Finally, utilizing our 5-axis CNC machining center, we completed the complex curved surfaces and side mounting holes in a single setup without re-fixturing, which significantly improved the positional accuracy relative to the center axis.

Ready to Manufacture Your Robot Parts?

Whether you need a single prototype or low-volume production of complex aluminum parts, we have the expertise to deliver. Click Here to Upload Your CAD Files

Our Manufacturing Capabilities

Capabilities include 3-Axis, 4-Axis, and 5-Axis CNC Milling, as well as CNC Turning operations. Standard materials processed include Aluminum alloys, Stainless Steel, Titanium, etc. and Engineering Plastics. Available secondary operations include Anodizing, Powder Coating, Bead Blasting, and Laser Engraving.

Capacity supports requirements ranging from single-unit Rapid Prototyping to Low-Volume Production runs (1-1,000+ units).

Factory Quality Assurance

A standardized Quality Management System (QMS) is applied to all manufacturing orders, regardless of part complexity or production volume. The following inspection stages are mandatory for every CNC machining project:

Order Fulfillment Process

From CAD to part.

FAQs About CNC Machining Services

Latest articles

March 3, 2026