Our Machining Projects

Why Choose Us?

-Custom parts from your drawings, no MOQ.

-End-to-end service: sourcing, machining, finishing & QC.

-Streamlined process = on-time delivery, every time.

CNC Machining Skeletonized Aluminum 7075 Drone Frame

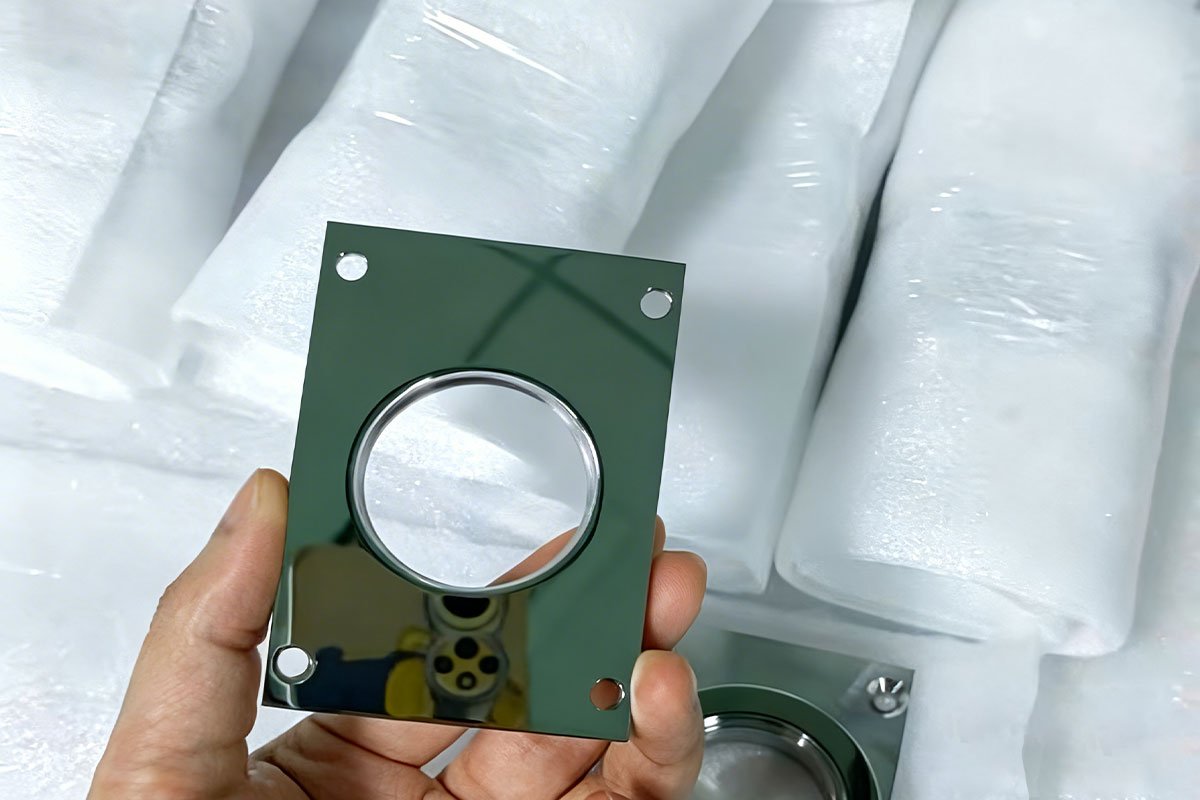

The component shown is a structural main plate serving as a CNC machined drone frame. The component shown is a structural main frame for a quadcopter. The design utilizes a truss/grid pattern to minimize weight while retaining structural rigidity. Aluminum 7075-T6 was specified as the raw material due to its higher yield strength compared to standard 6000-series alloys. The project required precise CNC milling to remove excess material followed by surface treatment for corrosion resistance.

Project Details

Part type: Skeletonized Quadcopter Frame / Main Plate

Material: Aluminum 7075-T6

Flatness Tolerance: ≤ 0.05mm

Surface Finish: Matte Black Anodizing (Type II)

Quantity: 82 pcs

Lead Time: 15 day

Manufacturing Process Details

The design requires significant material removal to form the grid structure. Aluminum 7075 is prone to warping when internal stresses are released during extensive machining. To maintain flatness, a symmetric machining strategy was employed. Material was removed sequentially from both sides of the plate. A stress-relief cycle was performed prior to the final finishing pass to stabilize the dimensions.

.The thin-walled, skeletonized structure offers limited surface area for clamping and is susceptible to deformation under clamping force. A custom fixture plate was utilized to secure the workpiece. Clamping pressure was distributed across the perimeter mounting points rather than the central grid to prevent crushing the ribs during the milling operation.

Post-machining, the frames underwent vibratory tumbling to remove sharp burrs generated by the milling tool. Subsequently, 120# bead blasting was applied to create a matte texture. Finally, the parts were black anodized to specification, providing a hardened, non-reflective surface layer.

Free Quote & Design Review

We provide custom CNC machining services for low-volume production and Rapid Prototyping for design verification. Click Here to Upload Your CAD Files

Our Manufacturing Capabilities

Capabilities include 3-Axis, 4-Axis, and 5-Axis CNC Milling, as well as CNC Turning operations. Standard materials processed include Aluminum alloys, Stainless Steel, Titanium, etc. and Engineering Plastics. Available secondary operations include Anodizing, Powder Coating, Bead Blasting, and Laser Engraving.

Capacity supports requirements ranging from single-unit Rapid Prototyping to Low-Volume Production runs (1-1,000+ units).

Factory Quality Assurance

A standardized Quality Management System (QMS) is applied to all manufacturing orders, regardless of part complexity or production volume. The following inspection stages are mandatory for every CNC machining project:

Order Fulfillment Process

From CAD to part.

FAQs About CNC Machining Services

Latest articles

March 3, 2026