Our Machining Projects

Why Choose Us?

-Custom parts from your drawings, no MOQ.

-End-to-end service: sourcing, machining, finishing & QC.

-Streamlined process = on-time delivery, every time.

CNC Machined Aluminum 7075 Prototypes

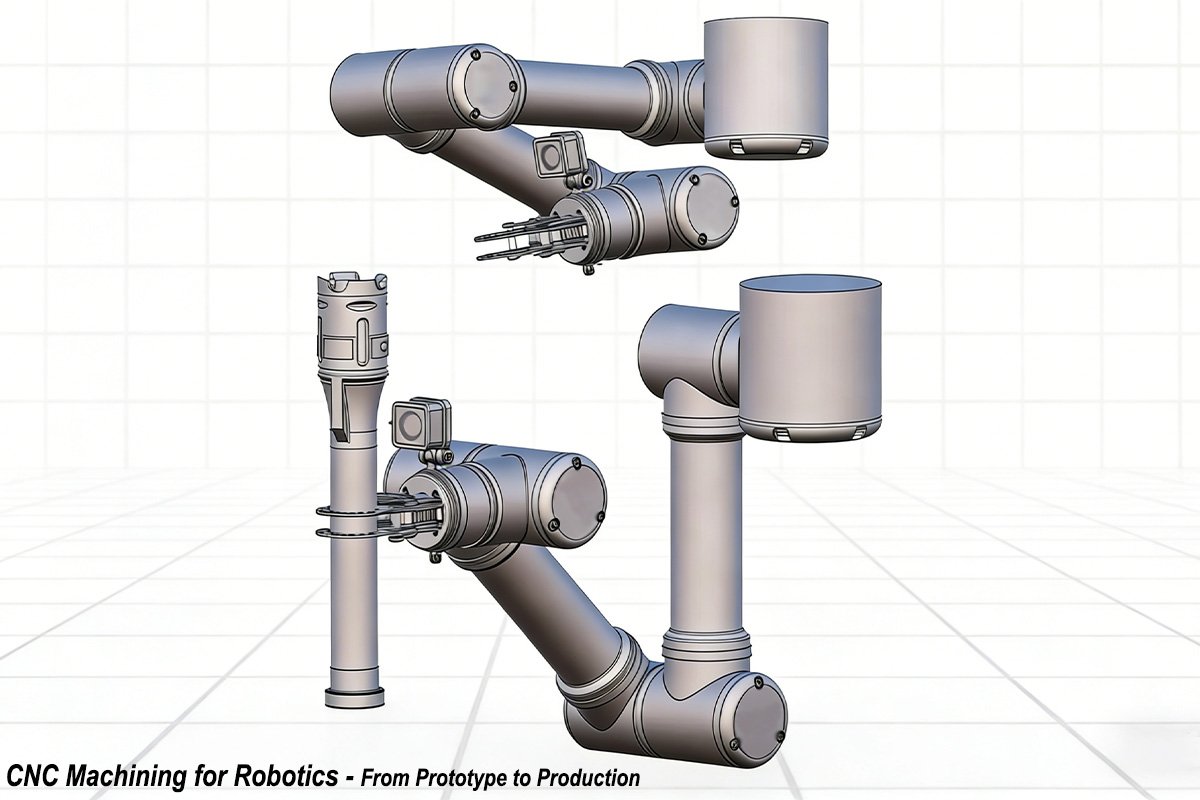

Lightweighting for Robotics: CNC Machined Aluminum 7075 Prototypes for Humanoid Robot ‘Upper Leg’ Components

From digital concept to physical reality—fast. That was the requirement for this custom robotics project. Our client required a functional CNC machined aluminum 7075 prototype to validate their robot’s walking mechanism before committing to expensive molds.

Why Aluminum 7075? Because the part serves as the primary load-bearing structure (the femur) and requires steel-like strength.

Project Details

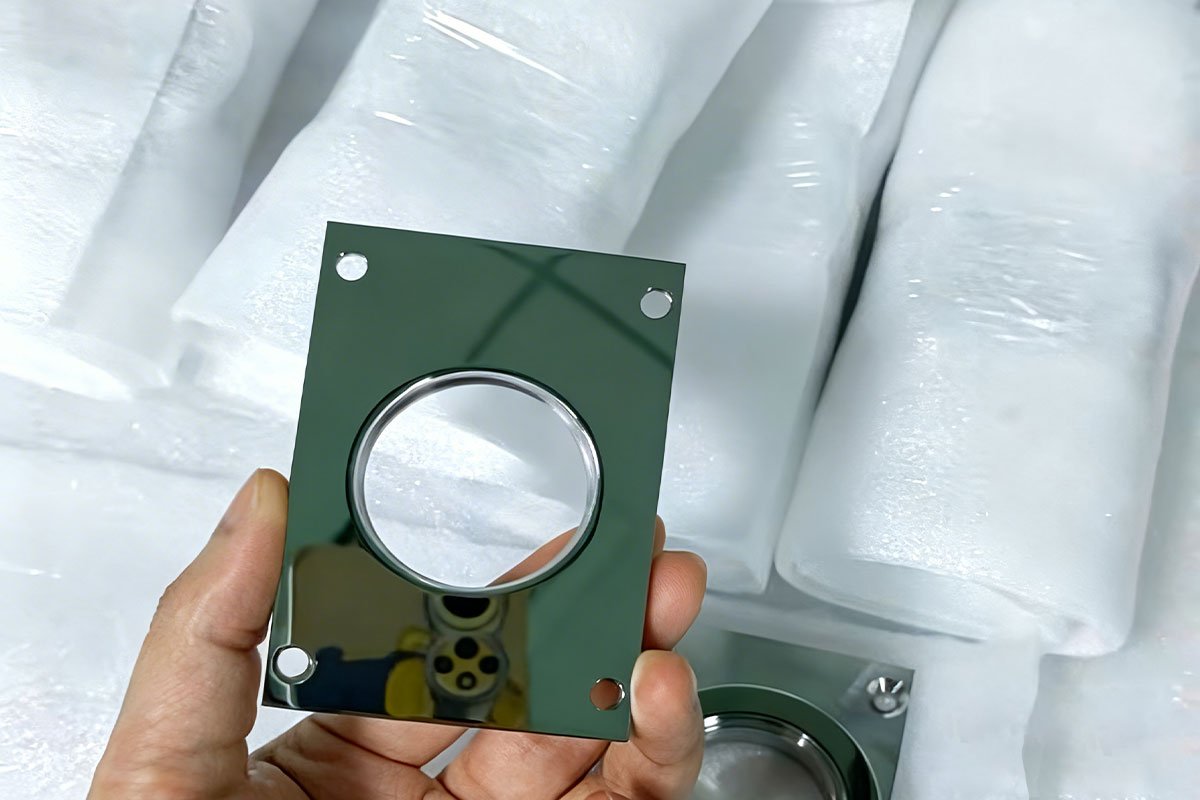

Part type: Upper Leg Link

Material: 7075-T6 aluminum

Dimensional tolerance: ±0.05 mm

Surface Finish: Black Anodizing

Batch quantity: 5 units

Delivery Time: 7 day

Why use Aluminum 7075 for your CNC Prototypes?

While Aluminum 6061 is the standard for general prototyping, CNC machined aluminum 7075 prototypes are the preferred choice for high-performance applications.:

High Strength: 7075 has a tensile strength of ~572 MPa (double that of 6061).

Fatigue Resistance: Ideal for parts under cyclic loading (like drone arms or suspension parts).

Machinability: Despite its hardness, 7075 chips break easily, allowing for excellent surface finishes when machined correctly.

Our Manufacturing Capabilities

Capabilities include 3-Axis, 4-Axis, and 5-Axis CNC Milling, as well as CNC Turning operations. Standard materials processed include Aluminum alloys, Stainless Steel, Titanium, etc. and Engineering Plastics. Available secondary operations include Anodizing, Powder Coating, Bead Blasting, and Laser Engraving.

Capacity supports requirements ranging from single-unit Rapid Prototyping to Low-Volume Production runs (1-1,000+ units).

Factory Quality Assurance

A standardized Quality Management System (QMS) is applied to all manufacturing orders, regardless of part complexity or production volume. The following inspection stages are mandatory for every CNC machining project:

Order Fulfillment Process

From CAD to part.

FAQs About CNC Machining Services

Latest articles

March 2, 2026