What is 5-Axis CNC Machining?

For intricate components featuring undercuts, contoured surfaces, or complex geometries, traditional 3-axis machining configurations often present significant challenges, frequently necessitating multiple manual repositioning steps. Our facility addresses these limitations by utilizing advanced 5-axis CNC milling centers.

This technology allows the cutting tool to approach the workpiece from all directions, precisely manipulating its position via trunnion tables or articulating heads. The result is single-setup machining of multifaceted components, which significantly reduces fixture errors and shortens lead times for demanding parts with intricate features.

Simultaneous 5-Axis vs. 3+2 Axis Machining

Simultaneous 5-Axis

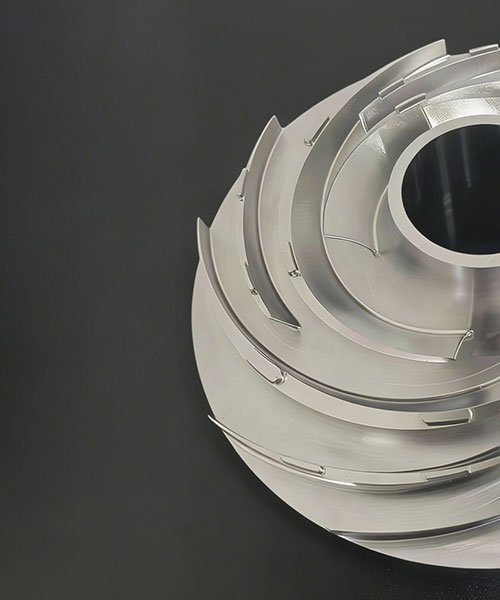

Simultaneous 5-Axis (Continuous): The machine moves all five axes (X, Y, Z, A, B/C) at the same time. This is required for organic shapes such as impellers, turbine blades, and anatomical implants. It ensures a smooth surface finish on curved surfaces.

3+2 Axis Machining

3+2 Axis (Positional): The machine locks the 4th and 5th axes in a fixed position while the 3 linear axes perform the cutting. This is used for parts requiring deep holes or features on multiple faces, improving tool rigidity and accuracy.

Industry Applications

Our 5-axis CNC machining capabilities are optimized for industries requiring high-precision components with complex geometries. We support engineers from prototyping through to low-volume production across the following sectors.

Aerospace & Defense

Aerospace components frequently demand thin-walled structures and aerodynamic profiles that are difficult to achieve with standard machining. Our 5-axis centers allow for shorter cutting tools, reducing vibration and ensuring tight tolerances on airfoil shapes and structural airframe parts. We process aerospace-grade materials including Aluminum 7075, Titanium.

Typical Applications:

- Turbine blades and impellers (Simultaneous 5-axis).

- Structural flanges and brackets.

- Landing gear components.

- Sensor housings for UAVs and drones.

Medical Devices

Medical manufacturing requires strict adherence to dimensional accuracy and surface finish requirements. 5-axis machining is essential for fabricating organic shapes found in anatomical implants and surgical robotics. Our process minimizes setup changes, maintaining the integrity of biocompatible materials like PEEK, Stainless Steel 316L, and Medical Grade Titanium.

Typical Applications:

- Orthopedic implants (knee and hip replacements).

- Surgical instruments and cutting guides.

- Bone screws and plates.

- Components for diagnostic equipment (MRI/CT scanners).

Automotive & Motorsport

We support the automotive sector with rapid prototyping and production of performance parts. 5-axis technology is utilized to machine complex internal features and undercuts often found in engine and transmission systems. This capability is critical for optimizing fluid dynamics in intake and exhaust components.

Typical Applications:

- Cylinder heads with custom porting.

- Turbocharger impellers and housings.

- Transmission casings and valve bodies.

- Complex manifolds for fluid systems.

Robotics & Automation

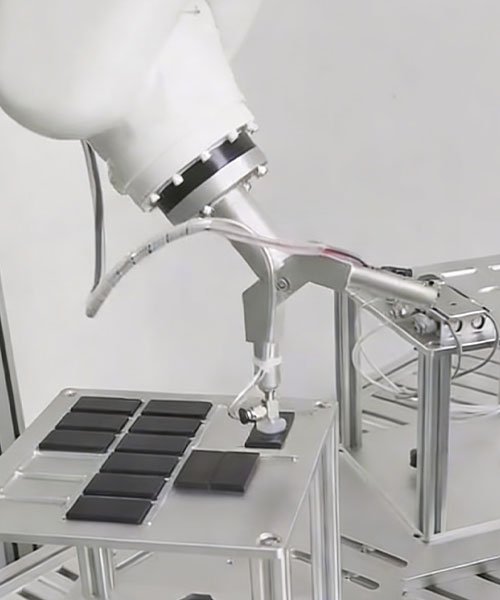

Robotic systems require lightweight yet rigid components with features on multiple planes. 5-axis positional machining (3+2) is efficient for creating mounting holes and pockets on different faces of robot arms and end-effectors without re-fixturing, ensuring precise alignment of axes.

Typical Applications:

- Robotic arm linkages and joints.

- End-of-arm tooling (EOAT).

- Custom grippers and fixtures.

- Base plates and structural housing.

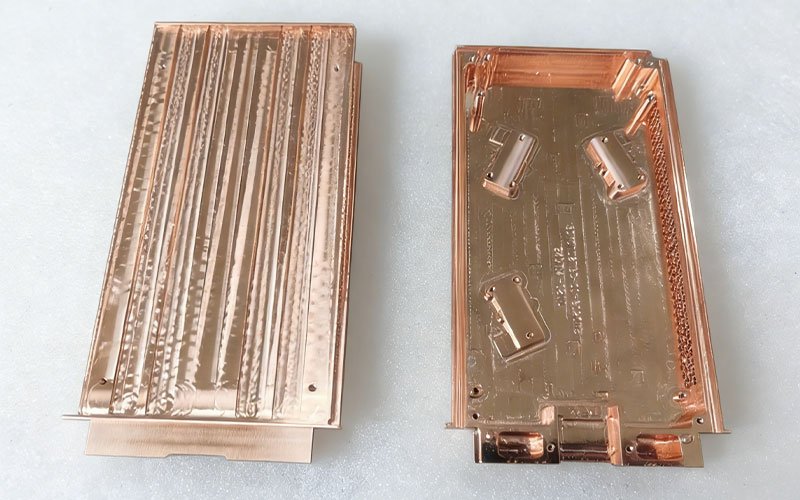

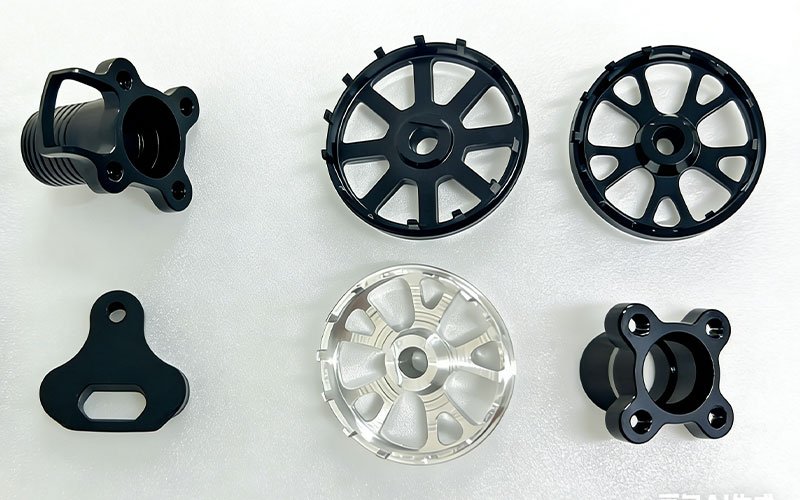

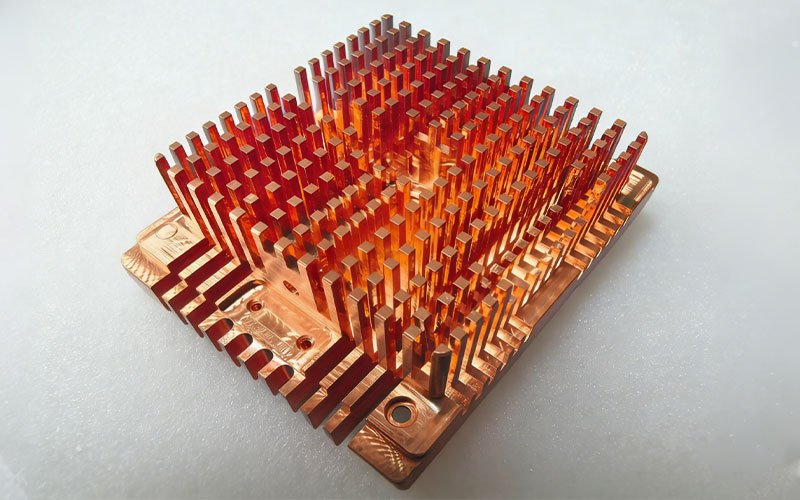

Our Portfolio

This portfolio shows some of our recent work — from one-off prototypes to low-volume production parts. We’ve done projects for aerospace, automotive, electronics and industrial fields, all made to meet exact client requirements and tight tolerances.

FAQs About CNC Machining Services