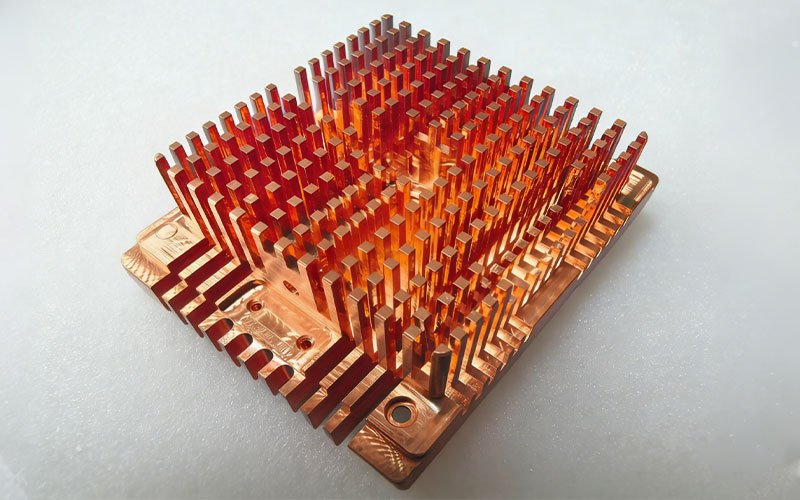

What is Rapid CNC Prototyping?

Rapid CNC prototyping is a fast, high-precision manufacturing process that uses computer numerical control (CNC) machines to fabricate custom prototypes from various materials (metal, plastic, etc.) according to your 3D design files. It combines the precision of traditional CNC machining with the efficiency of rapid prototyping, suitable for small-batch prototype trial production, product development verification, and functional testing. Unlike 3D printing, it uses real production materials to ensure that the prototype’s performance is consistent with the mass-produced products.

Why Choose CNC Machining over 3D Printing?

Real Materials

Test your design with production-grade materials, not simulants. Get the exact mechanical properties you need.

Tight Tolerances

Achieve standard tolerances of +/- 0.005mm, ensuring your prototype fits and functions perfectly.

Superior Finishes

No layer lines. Get smooth surfaces ready for painting, anodizing, or polishing.

Rapid CNC Prototyping vs. 3D Printing Prototyping

Rapid CNC Prototyping

3D Printing Prototyping

3D Printing Prototyping (additive manufacturing) stacks materials layer by layer for prototype production, which is characterized by lower cost and faster delivery speed. Compared with Rapid CNC Prototyping, it has fewer material options.

Rapid CNC Prototyping Material Selection

Our facility works with a wide range of metals, plastics, and composites. Below is a list of the materials we frequently machine.

Delrin® CNC Machining

Acrylic CNC Machining

CNC Machining Finishes

Improve part performance and appearance. We offer a wide range of finishes to ensure wear resistance and corrosion protection. Explore our mechanical and chemical options below.

As-machined

Anodizing

Bead Blasting

Powder Coating & Wet Painting

Metal Plating

Part Marking

Rapid CNC Prototyping Machining Tolerances

We provide high-precision machining capable of holding tolerances down to ±0.005mm for critical features. This level of accuracy ensures that components strictly adhere to your dimensional specifications and assembly requirements.

| Category | Description |

| General Tolerances | Unless otherwise specified, standard tolerances for metals are ± 0.127 mm (± 0.005″) in accordance with ISO 2768-m. Tolerances for plastics and composites are generally ± 0.254 mm (± 0.010″) due to material properties. |

| Min Wall Thickness | Metals: 0.8 mm Plastics: 1.5 mm |

| Minimum Feature Size | 0.5 mm |

| Threads & Tapped Holes | M2 / #2-56 (Minimum) We can also machine custom threads. |

| Surface Finish | Unless post-processing is requested, parts are supplied with an as-machined surface of Ra 3.2 μm (125 μin). Visible tool marks may be present. |

| Edge Condition | Broken Edges (Deburred) |

| Maximum Part Size | CNC Milling: 4000×1500×600 mm; CNC Turning: 200×500 mm |

| Minimum Part Size | CNC Milling: 5×5×5 mm; CNC Turning: 2×2 mm |

Free Engineering Support & DFM

We don’t just machine; we verify. Every order includes a comprehensive Design for Manufacturing (DFM) review. We’ll flag sharp corners, deep pockets, or thin walls that might increase cost or risk, helping you optimize your design before cutting metal.

Bridge the Gap Between Concept and Production

Move from prototyping to low-volume production seamlessly. Because we use the same equipment for prototypes as we do for production runs, your transition will be smooth, with no surprises in quality or tolerance.

FAQs About CNC Machining Services