Our Machining Projects

Why Choose Us?

-Custom parts from your drawings, no MOQ.

-End-to-end service: sourcing, machining, finishing & QC.

-Streamlined process = on-time delivery, every time.

Precision CNC Turning of Flexspline Blanks for Harmonic Drives

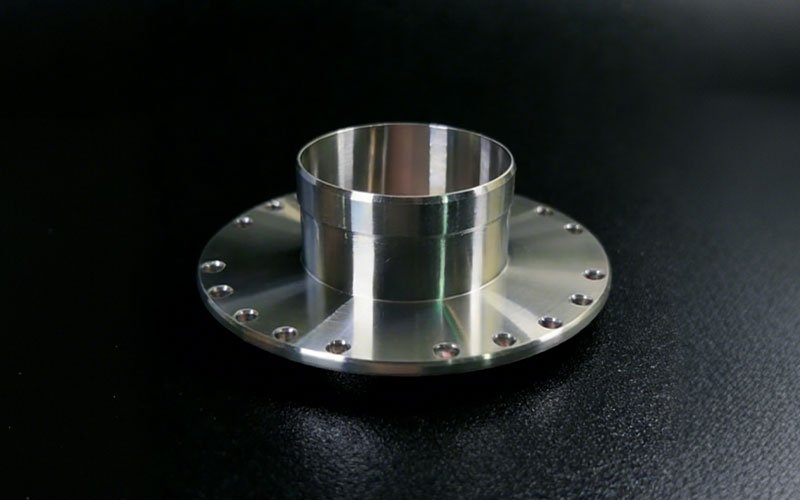

The component shown illustrates the precision CNC turning of flexspline blanks, which constitutes the initial manufacturing stage of a harmonic drive. Before gear teeth can be generated, the raw material is machined into a precision thin-walled cup. This stage establishes the critical geometric datums for the entire component. The primary engineering objective is to achieve absolute wall thickness uniformity, as any variation here will result in uneven stress distribution and transmission error in the final assembly.

Project Details

Part type: Flexspline Blank (Pre-Toothed)

Material: 40CrNiMoA Alloy Steel

Quantity: 80 pcs

Lead Time: 20 day

Manufacturing Challenges

The machining of thin-walled flexspline blanks presents significant difficulties regarding deformation and vibration. To guarantee the 0.003mm wall thickness uniformity required for this component, specific tooling and process strategies were implemented. We utilized a high-precision Hydraulic Expanding Mandrel. Unlike mechanical jaws, this fixture applies uniform hydrostatic pressure against the entire internal circumference of the workpiece. This method supports the thin wall from the inside, eliminating radial distortion and ensuring the turned outer diameter remains perfectly concentric to the inner bore. A specialized turning process was developed to minimize radial cutting pressure.

Free Quote & Design Review

We provide custom CNC machining services for low-volume production and Rapid Prototyping for design verification. Click Here to Upload Your CAD Files

Our Manufacturing Capabilities

Capabilities include 3-Axis, 4-Axis, and 5-Axis CNC Milling, as well as CNC Turning operations. Standard materials processed include Aluminum alloys, Stainless Steel, Titanium, etc. and Engineering Plastics. Available secondary operations include Anodizing, Powder Coating, Bead Blasting, and Laser Engraving.

Capacity supports requirements ranging from single-unit Rapid Prototyping to Low-Volume Production runs (1-1,000+ units).

Factory Quality Assurance

A standardized Quality Management System (QMS) is applied to all manufacturing orders, regardless of part complexity or production volume. The following inspection stages are mandatory for every CNC machining project:

Order Fulfillment Process

From CAD to part.

FAQs About CNC Machining Services

Latest articles

February 20, 2026

February 20, 2026

February 20, 2026