Our Machining Projects

Why Choose Us?

-Custom parts from your drawings, no MOQ.

-End-to-end service: sourcing, machining, finishing & QC.

-Streamlined process = on-time delivery, every time.

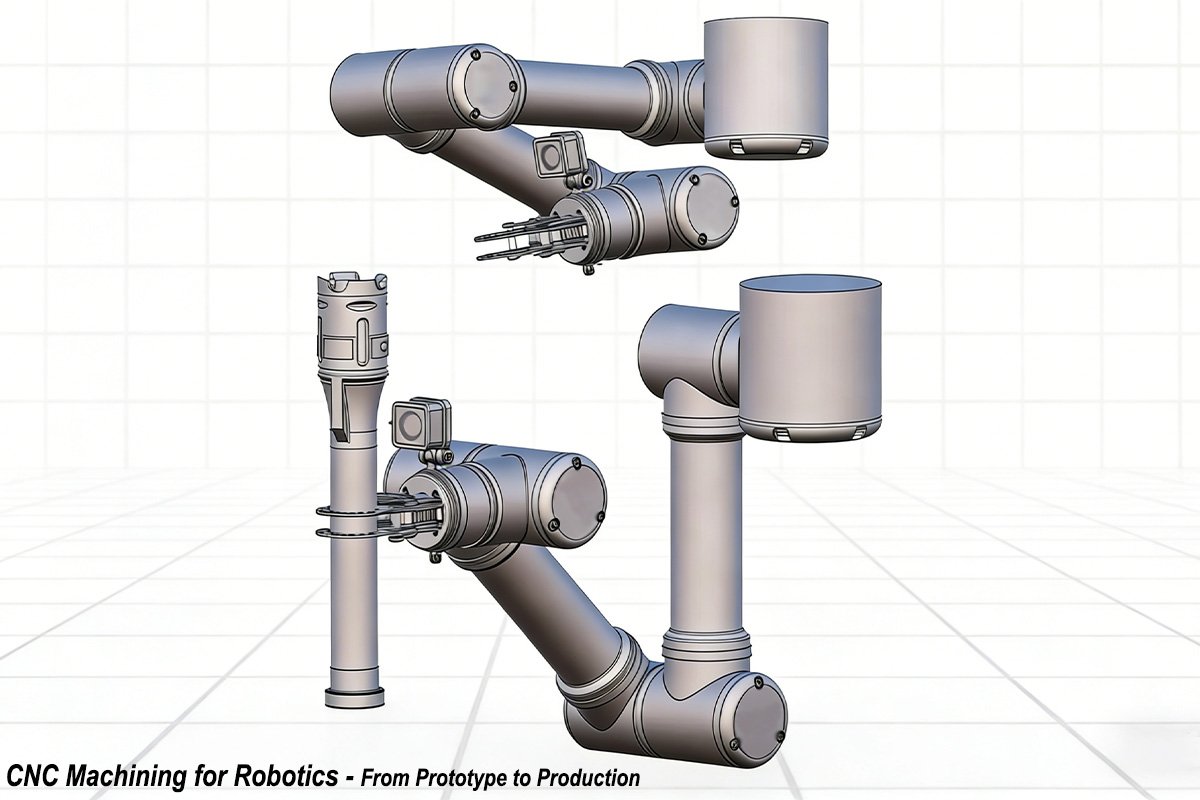

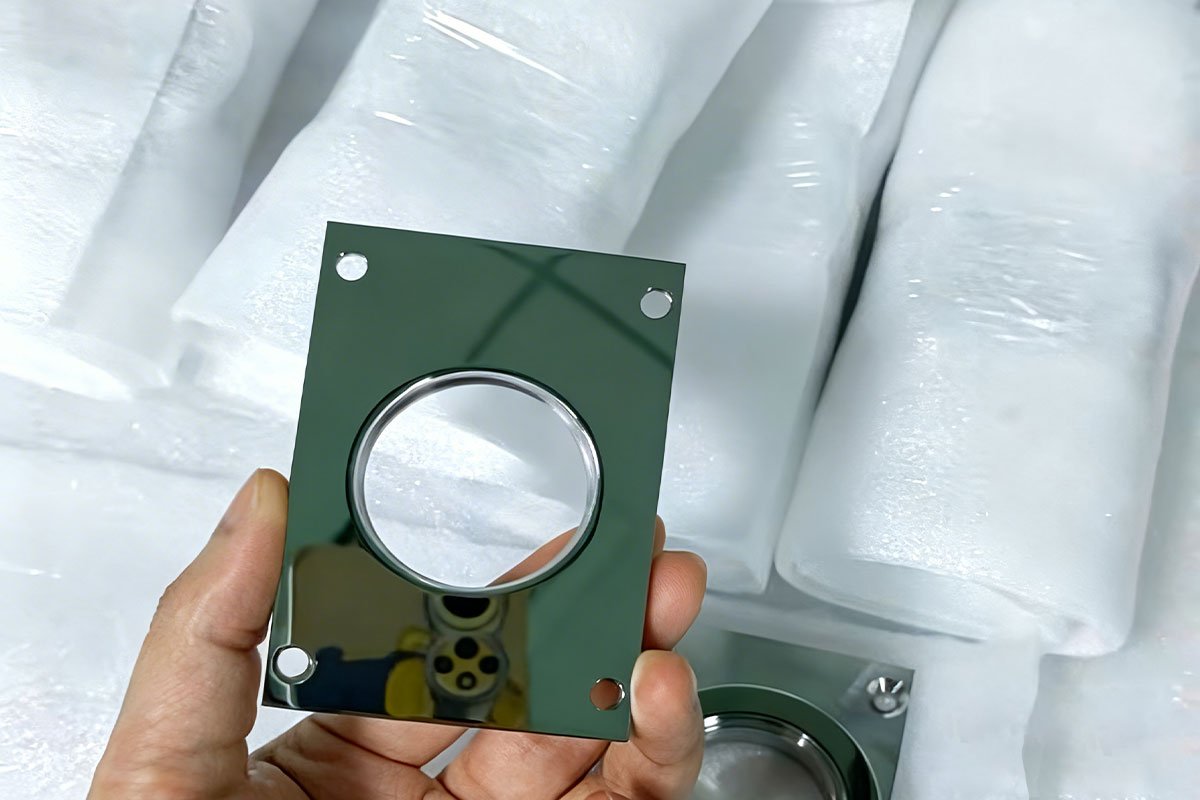

Magnesium CNC Machining Case: Lightweighting Robot Arm Shell

A European startup specializing in advanced robotics research approached us with a critical goal: reducing the weight of their next-generation robot arm. Recognizing that magnesium offers a superior strength-to-weight ratio compared to aluminum, they sought our expertise in Magnesium CNC Machining to fabricate a custom housing that maximizes agility without compromising durability.

Project Details

Part type: Robot Arm Shell

Material: Magnesium Alloy AZ31B

Dimensional tolerance: ±0.1 mm

Quantity: 50 pcs

Lead Time: 20 day

How We Handle Magnesium AZ31B

Magnesium alloy CNC machining comes with specific challenges: its low hardness makes it prone to tool adhesion and workpiece deformation during clamping. The fine, flammable chips require specialized chip removal systems to avoid fire risks.

Machining magnesium requires strict adherence to safety protocols. At XINGDA CNC, we eliminate the risks of flammability and deformation through a controlled manufacturing process:

- Coolant Strategy: We utilize specialized mineral-oil-based coolants to dissipate heat effectively and prevent hydrogen generation, ensuring a 100% safe machining environment.

- Tooling Optimization: Our engineers select high-polished, uncoated carbide tools with specific geometries to ensure rapid chip evacuation and minimize friction heat.

- Chip Management: We adhere to a “heavy chip load” strategy. By avoiding dwelling and maintaining consistent feed rates, we generate thicker chips that carry heat away from the part, preventing ignition risks associated with fine dust.

Looking for a Reliable Partner for Magnesium Parts?

With our professional one-stop CNC machining services and strict quality assurance, we deliver international-standard quality at the speed of the Greater Bay Area supply chain. Need your prototype finished in as fast as 5 days? Let’s discuss your specific requirements—contact us now.

Our Manufacturing Capabilities

Capabilities include 3-Axis, 4-Axis, and 5-Axis CNC Milling, as well as CNC Turning operations. Standard materials processed include Aluminum alloys, Stainless Steel, Titanium, etc. and Engineering Plastics. Available secondary operations include Anodizing, Powder Coating, Bead Blasting, and Laser Engraving.

Capacity supports requirements ranging from single-unit Rapid Prototyping to Low-Volume Production runs (1-1,000+ units).

Factory Quality Assurance

A standardized Quality Management System (QMS) is applied to all manufacturing orders, regardless of part complexity or production volume. The following inspection stages are mandatory for every CNC machining project:

Order Fulfillment Process

From CAD to part.

FAQs About CNC Machining Services

Latest articles

March 3, 2026