Our Machining Projects

Why Choose Us?

-Custom parts from your drawings, no MOQ.

-End-to-end service: sourcing, machining, finishing & QC.

-Streamlined process = on-time delivery, every time.

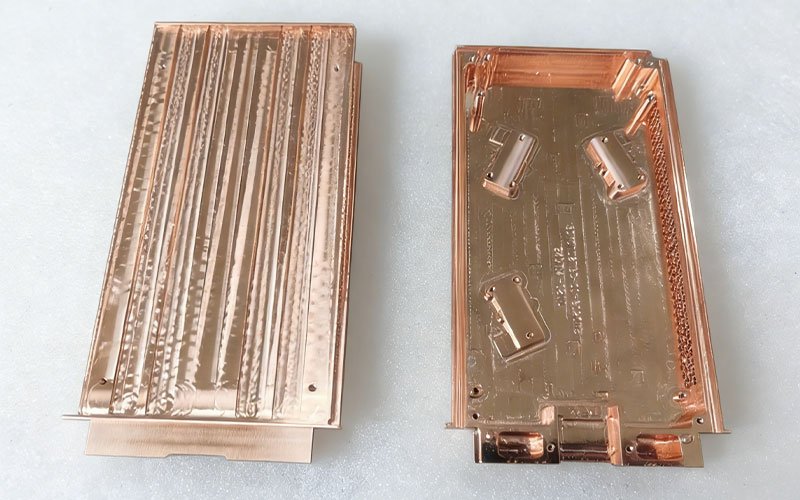

CNC Machined Copper Parts: Enclosures for Vapor Chambers

In the realm of high-performance computing and 5G telecommunications, thermal density is rising exponentially. Recently, a thermal engineering client approached us with a critical bottleneck: their latest processor design was generating heat flux levels that traditional aluminum heat sinks could not dissipate efficiently. To prevent system throttling, they transitioned to a two-phase cooling solution—a custom Vapor Chamber (VC).

The internal design featured intricate capillary channels and support islands that were too complex for stamping and required tolerances too tight for die-casting.

This case study details how we addressed this challenge by producing high-precision CNC Machined Copper Parts from solid Oxygen-Free Copper (C11000). By optimizing our toolpaths for soft metals and utilizing vacuum fixturing to maintain flatness, we successfully delivered enclosures that allowed the client’s vapor chamber to function at peak efficiency, solving their thermal crisis.

Project Details

Part type: Custom Copper Thermal Management Enclosure

Material: Copper C11000

Quantity: 58 pcs

Lead Time: 38 day

Free Quote & Design Review

We provide custom CNC machining services for low-volume production and Rapid Prototyping for design verification. Click Here to Upload Your CAD Files

Our Manufacturing Capabilities

Capabilities include 3-Axis, 4-Axis, and 5-Axis CNC Milling, as well as CNC Turning operations. Standard materials processed include Aluminum alloys, Stainless Steel, Titanium, etc. and Engineering Plastics. Available secondary operations include Anodizing, Powder Coating, Bead Blasting, and Laser Engraving.

Capacity supports requirements ranging from single-unit Rapid Prototyping to Low-Volume Production runs (1-1,000+ units).

Factory Quality Assurance

A standardized Quality Management System (QMS) is applied to all manufacturing orders, regardless of part complexity or production volume. The following inspection stages are mandatory for every CNC machining project:

Order Fulfillment Process

From CAD to part.

FAQs About CNC Machining Services

Latest articles

February 20, 2026

February 20, 2026

February 20, 2026