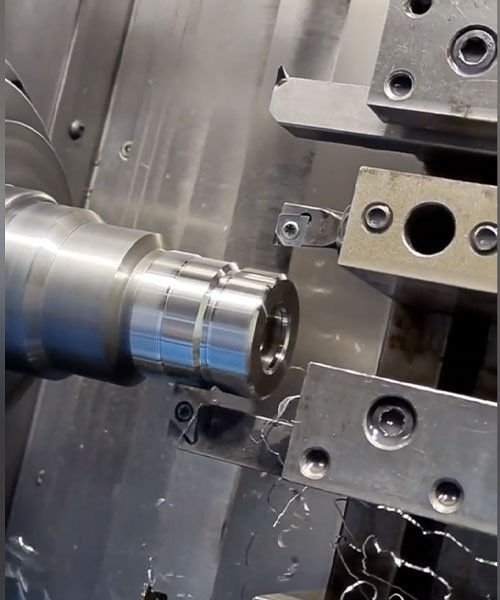

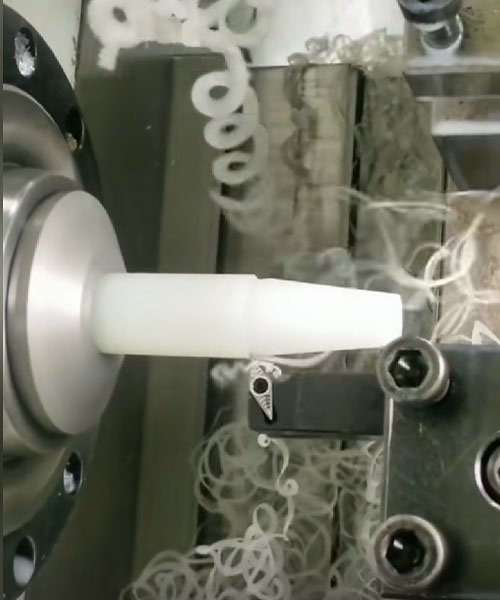

What is CNC Turning?

CNC turning is a subtractive manufacturing process where the workpiece rotates at high speed while a stationary cutting tool removes material. This process is primarily used to create cylindrical parts with external and internal features. Our facility utilizes both standard 2-axis lathes and turning centers with live tooling. This allows us to machine simple pins as well as complex components with off-axis features in a single setup.

Standard 2-Axis Turning

The most common setup for machining symmetrical, cylindrical parts. The cutting tool moves on the X and Z axes to perform operations such as facing, outer diameter (OD) turning, boring, grooving, and threading.

CNC Turn-Mill

Live tooling allows the lathe turret to drive rotating milling cutters (drills, end mills) while the workpiece is held in the spindle. This capability enables the machining of features such as flats, cross-holes, and slots without moving the part to a separate milling machine.

CNC Turning Materials

CNC turning operations primarily utilize raw material in the form of bar stock (cylindrical rods). We maintain a diverse inventory of metal and plastic rod stock to support various functional requirements. Below are the specific material grades commonly used in our turning centers.

Metal CNC Turning

- Aluminum: 6061-T6, 7075-T6, 2024.

- Stainless Steel: 303 (Free-machining), 304, 316L, 17-4PH.

- Brass & Copper: C360 (Free-machining brass), C110.

- Steel & Titanium: 1018, 4140, Titanium Gr2 & Gr5.

Plastic CNC Milling

- Delrin (POM)

- Nylon

- PTFE,

- PEEK

- ABS

- Polycarbonate

CNC Machining Tolerances

We provide high-precision machining capable of holding tolerances down to ±0.005mm for critical features. This level of accuracy ensures that components strictly adhere to your dimensional specifications and assembly requirements.

| Category | Description |

| General Tolerances | Unless otherwise specified, standard tolerances for metals are ± 0.127 mm (± 0.005″) in accordance with ISO 2768-m. Tolerances for plastics and composites are generally ± 0.254 mm (± 0.010″) due to material properties. |

| Min Wall Thickness | Metals: 0.8 mm Plastics: 1.5 mm |

| Minimum Feature Size | 0.5 mm |

| Threads & Tapped Holes | M2 / #2-56 (Minimum) We can also machine custom threads. |

| Surface Finish | Unless post-processing is requested, parts are supplied with an as-machined surface of Ra 3.2 μm (125 μin). Visible tool marks may be present. |

| Edge Condition | Broken Edges (Deburred) |

| Maximum Part Size | CNC Milling: 4000×1500×600 mm; CNC Turning: 200×500 mm |

| Minimum Part Size | CNC Milling: 5×5×5 mm; CNC Turning: 2×2 mm |

FAQs About CNC Machining Services

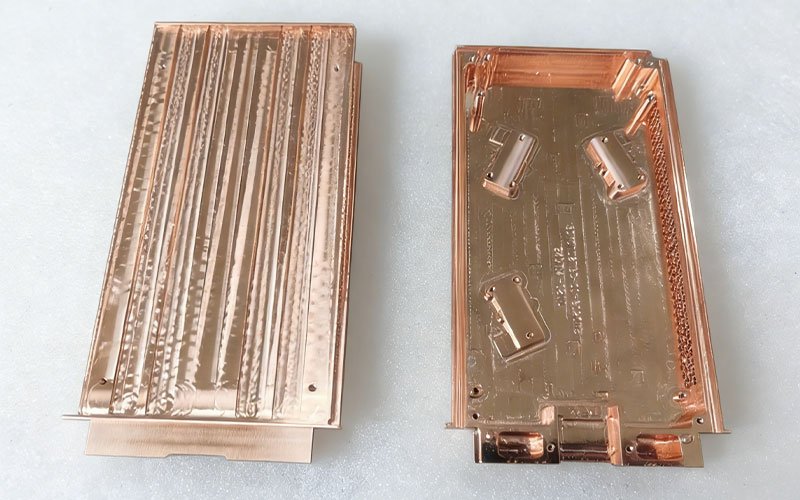

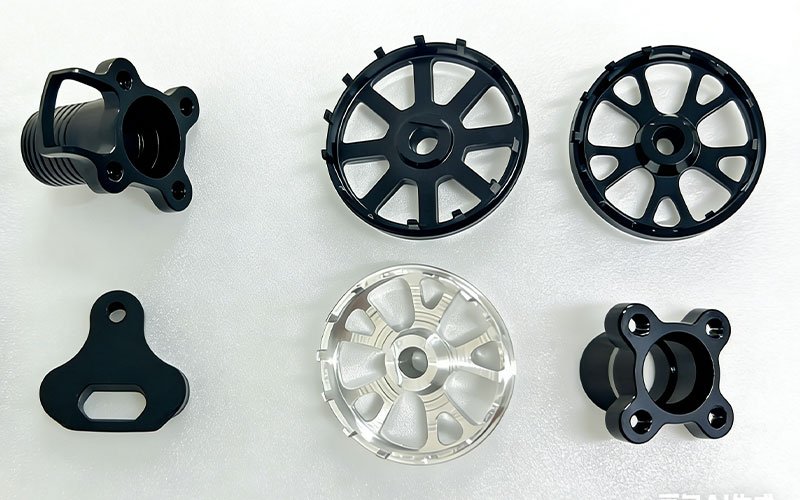

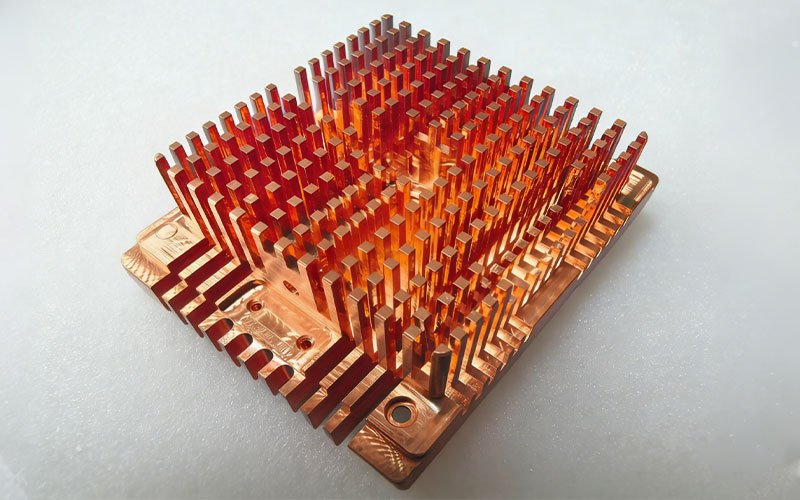

Our Portfolio

This portfolio shows some of our recent work — from one-off prototypes to low-volume production parts. We’ve done projects for aerospace, automotive, electronics and industrial fields, all made to meet exact client requirements and tight tolerances.