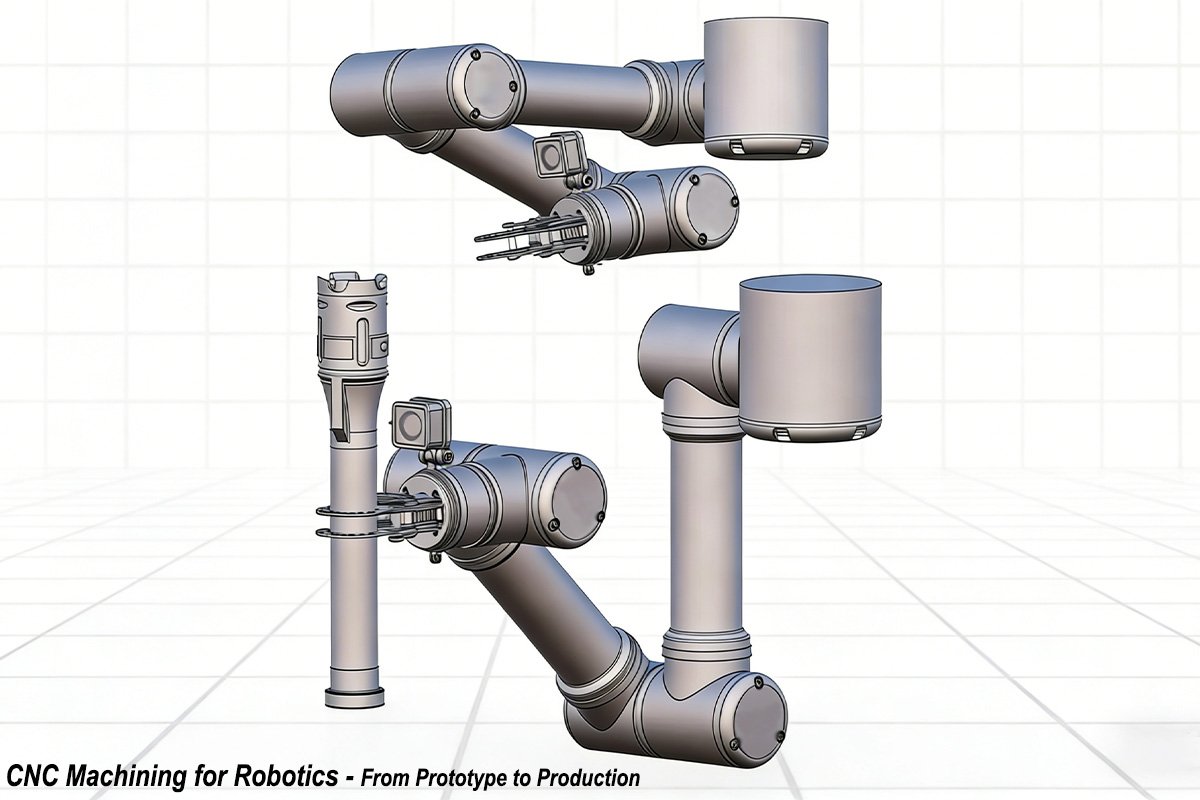

Custom Aluminum Robotics Parts Machining Services: Precision & Speed

Your spend weeks perfecting the CAD, but finding a shop that actually understands your design? That’s a whole other headache.

That’s exactly where we come in. We don’t just cut metal; we provide Custom Aluminum Robotics Parts Machining Services that actually make sense for your project. Whether it’s a prototype or a small batch run, we know that “close enough” doesn’t cut it in robotics.

Why Choose Aluminum for Robotics Parts?

If you ask ten robotics engineers about their favorite material, nine of them will likely answer aluminum. Why? Because it hits the perfect sweet spot in manufacturing processes.

- It’s Light (But Not Weak): Aluminum is about one-third the weight of steel. In robotics, less weight means less inertia. This allows your robot arms to move faster and stop precisely without shaking like a leaf. For custom aluminum robotics parts machining, this strength-to-weight ratio is the biggest selling point.

- It Keeps Things Cool: Motors get hot. Electronics get hot. Aluminum is naturally conductive, acting like a built-in heat sink. It pulls heat away from critical components, so you don’t always need to add bulky cooling fans.

- It’s Friendly to Your Budget: Titanium is cool, but have you seen the price tag? And machining steel takes forever. Aluminum is soft enough to machine at high speeds (saving you money on machine time) but strong enough to hold tight tolerances.

Material Selection: 6061 vs 7075 Aluminum

If you ask ten robotics engineers about their favorite material, nine of them will likely answer aluminum. Why? Because it hits the perfect sweet spot in manufacturing processes.

- It’s Light (But Not Weak): Aluminum is about one-third the weight of steel. In robotics, less weight means less inertia. This allows your robot arms to move faster and stop precisely without shaking like a leaf. For custom aluminum robotics parts machining, this strength-to-weight ratio is the biggest selling point.

- It Keeps Things Cool: Motors get hot. Electronics get hot. Aluminum is naturally conductive, acting like a built-in heat sink. It pulls heat away from critical components, so you don’t always need to add bulky cooling fans.

- It’s Friendly to Your Budget: Titanium is cool, but have you seen the price tag? And machining steel takes forever. Aluminum is soft enough to machine at high speeds (saving you money on machine time) but strong enough to hold tight tolerances.

6061 Aluminum: The Versatile Workhorse

6061 is one of the most widely used aluminum alloys in CNC machining, valued for its excellent balance of strength, corrosion resistance, and ease of fabrication. Alloyed with magnesium and silicon, it offers moderate tensile strength (up to 310 MPa when heat-treated to T6 temper) and can be readily welded, machined, or formed—key advantages for prototyping and low-to-medium volume production.

7075 Aluminum: The High-Strength Performer

7075 is a high-strength aluminum alloy alloyed with zinc, magnesium, and copper—often referred to as the “aircraft grade” aluminum for its exceptional tensile strength (up to 572 MPa in T6 temper). It delivers strength comparable to some steels while maintaining aluminum’s lightweight benefits, making it a top pick for high-stress applications where durability is non-negotiable.

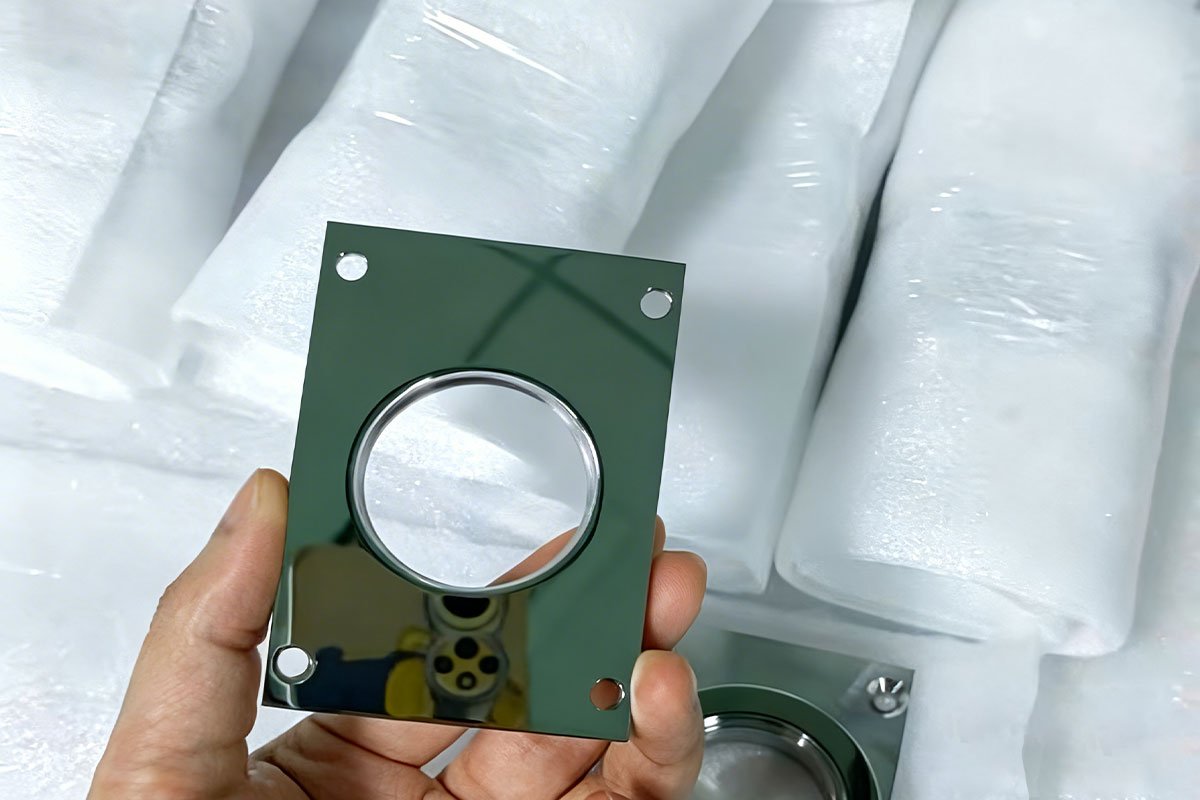

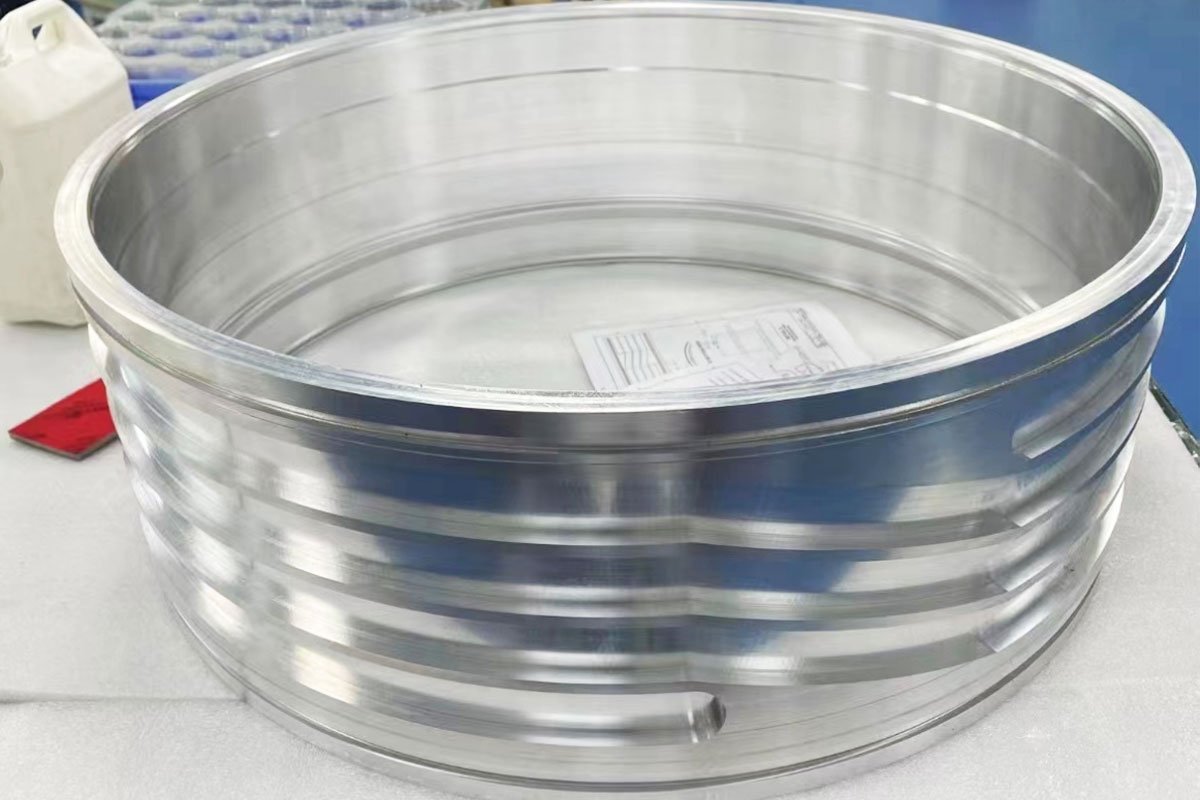

Case Study: 5-Axis CNC Machined 7075 Aluminum Robot Joint Component

Client & Requirement: A collaborative robot (cobot) manufacturer needed a high-precision, load-bearing joint component (as shown in the product image) for their 6-axis cobot arm. The part required:

The circular mounting holes have strict tolerance requirements (±0.05mm);

Lightweight design to avoid increasing the cobot’s arm inertia.

The joint (seen in the image) features a curved, asymmetric profile with a central bore and 16 evenly spaced mounting holes—traditional 3-axis CNC could not machine the curved surfaces and holes in a single setup, risking alignment errors. Additionally, the part needed to withstand repeated torque stress without deformation.

Solution: 7075-T6 Aluminum + 5-Axis CNC Machining

7075 alloy’s inherent dimensional stability—paired with a pre-machining stress relief heat treatment (to eliminate residual stresses from material forging)—minimized machining deformation, which was critical for maintaining the ±0.05mm tolerance of the precise mounting holes. For the complex geometry, we used simultaneous 5-axis cutting: this process machined the curved profile, central bore, and all 16 mounting holes in one setup—eliminating re-clamping errors (a common source of hole misalignment) while reducing production lead time by 30%.

Quality Assurance: How We Ensure Precision

At Hardware Rapid, precision is built into every CNC-machined part. Our quality check process centers on Coordinate Measuring Machine (CMM) inspection to meet tight tolerance requirements.

CMM provides accurate 3D measurements of all key features, from hole positions to curved surfaces, ensuring each part matches design specs.

Conclusion

At the end of the day, Custom Aluminum Robotics Parts Machining is about speed, precision, and trust.

You’ve seen our work on the robotic joint module. We can bring that same level of quality to your project, helping you move from “CAD file” to “Finished Product” faster than you thought possible.

Share this article

Written by : Alex

A quick overview of the topics covered in this article.

Latest articles

March 2, 2026