Our Machining Projects

Why Choose Us?

-Custom parts from your drawings, no MOQ.

-End-to-end service: sourcing, machining, finishing & QC.

-Streamlined process = on-time delivery, every time.

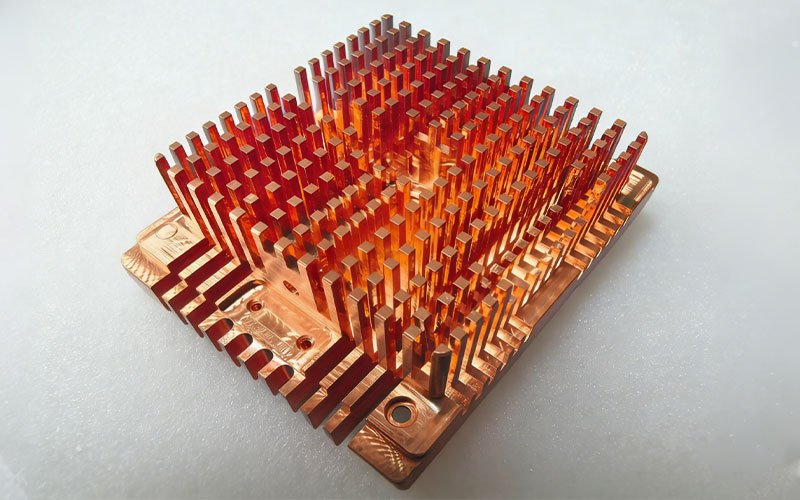

Custom CNC Machined Copper Pin Fin Heatsink

A client contacted us for the machining of a custom thermal component. The part is a copper heatsink made from C11000 alloy. We completed the manufacturing process using a 3-axis CNC machining center strictly according to the customer’s drawings. Unlike standard extruded or skived heatsinks, our CNC machining process allows for complex base features, mounting holes, and varying heights to perfectly fit your device layout.

Project Details

Part type: Custom Pin Fin Copper Heatsink

Material: Copper C11000 (Electrolytic Tough Pitch – ETP)

Quantity: 20 pcs

Lead Time: 15 day

The Comparison: Skiving vs. CNC

Skived Fin Technology:

This process involves slicing thin layers of metal from a block to form fins. It allows for very thin fins and high density without solder joints. However, Skiving is generally limited to straight, linear fins (rail shape) and requires a consistent base thickness.

CNC Machining (Our Approach):

CNC milling removes material to create shapes. While it can be more time-consuming, it offers unlimited design flexibility. It allows for the creation of Pin Fins (square or round columns), complex base features, mounting holes, and cutouts in a single setup.

Free Quote & Design Review

We provide custom CNC machining services for low-volume production and Rapid Prototyping for design verification. Click Here to Upload Your CAD Files

Our Manufacturing Capabilities

Capabilities include 3-Axis, 4-Axis, and 5-Axis CNC Milling, as well as CNC Turning operations. Standard materials processed include Aluminum alloys, Stainless Steel, Titanium, etc. and Engineering Plastics. Available secondary operations include Anodizing, Powder Coating, Bead Blasting, and Laser Engraving.

Capacity supports requirements ranging from single-unit Rapid Prototyping to Low-Volume Production runs (1-1,000+ units).

Factory Quality Assurance

A standardized Quality Management System (QMS) is applied to all manufacturing orders, regardless of part complexity or production volume. The following inspection stages are mandatory for every CNC machining project:

Order Fulfillment Process

From CAD to part.

FAQs About CNC Machining Services

Latest articles

February 20, 2026

February 20, 2026

February 20, 2026