Our Machining Projects

Why Choose Us?

-Custom parts from your drawings, no MOQ.

-End-to-end service: sourcing, machining, finishing & QC.

-Streamlined process = on-time delivery, every time.

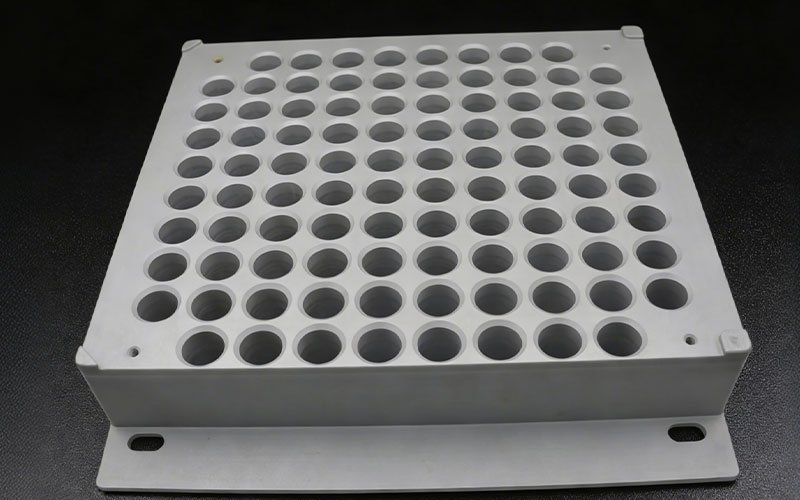

Custom Dry Bath Block CNC Machining

Our client, a manufacturer of analytical laboratory instruments, required a specialized component for their new series of benchtop incubators. The part is a custom dry bath block, designed to hold specific sample vials during thermal cycling processes. Unlike standard off-the-shelf test tube holders, this component required a unique hole arrangement and custom depth dimensions to accommodate the client’s proprietary glassware. The primary objective was to ensure rapid and uniform thermal conductivity across the entire aluminum block.

Project Details

Part type: Custom Dry Bath Block / Reaction Module

Material: Aluminum Alloy 6061-T6

Quantity: 15 pcs

Lead Time: 11 day

Free Quote & Design Review

We provide custom CNC machining services for low-volume production and Rapid Prototyping for design verification. Click Here to Upload Your CAD Files

Our Manufacturing Capabilities

Capabilities include 3-Axis, 4-Axis, and 5-Axis CNC Milling, as well as CNC Turning operations. Standard materials processed include Aluminum alloys, Stainless Steel, Titanium, etc. and Engineering Plastics. Available secondary operations include Anodizing, Powder Coating, Bead Blasting, and Laser Engraving.

Capacity supports requirements ranging from single-unit Rapid Prototyping to Low-Volume Production runs (1-1,000+ units).

Factory Quality Assurance

A standardized Quality Management System (QMS) is applied to all manufacturing orders, regardless of part complexity or production volume. The following inspection stages are mandatory for every CNC machining project:

Order Fulfillment Process

From CAD to part.

FAQs About CNC Machining Services

Latest articles

February 20, 2026

February 20, 2026

February 20, 2026