CNC Machining Services for Industrial and Defense UAV Applications

Early UAV development focused primarily on consumer-grade quadcopters designed for recreational use. These devices typically carry minimal payloads and operate for short durations. In contrast, modern industrial UAVs are deployed for tasks such as aerial surveying, agriculture, and logistics. These applications require the airframe to support heavier optical or mechanical payloads and withstand continuous operation in variable weather conditions.

Industrial Drone

Consumer-grade drones often utilize injection-molded plastics to minimize manufacturing costs. However, plastic components present limitations regarding tensile strength, thermal expansion, and vibration damping when subjected to industrial workloads. Under high-load or high-frequency vibration scenarios, plastic parts may exhibit structural fatigue or dimensional instability.

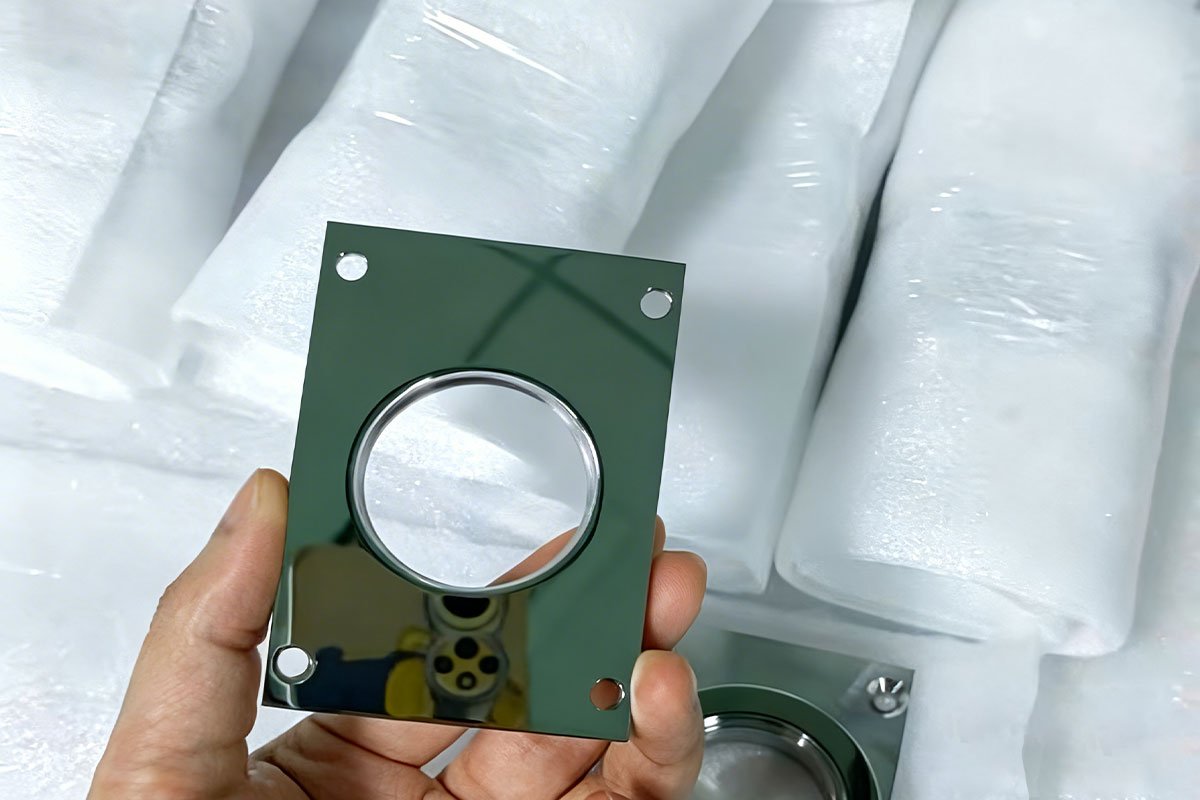

To address these mechanical constraints, the manufacturing specification for UAV components has shifted toward CNC Machining. The use of aluminum alloys (such as 7075 and 6061) allows for components that offer higher stiffness-to-weight ratios compared to plastics. Furthermore, CNC machining provides the micron-level tolerances required for precise motor alignment and structural assembly, which are critical for the stability of industrial platforms.

Military Drone

Beyond commercial and industrial sectors, UAVs are utilized in defense for Intelligence, Surveillance, and Reconnaissance (ISR) missions. These tactical environments impose the most rigorous mechanical demands, requiring airframes to withstand rapid acceleration, high-impact landings, and exposure to extreme temperature ranges or corrosive elements.

To comply with Military Specifications (Mil-Spec), components must demonstrate absolute reliability where structural failure is not an option. CNC Machining is the primary manufacturing method for these applications due to its ability to process high-strength materials such as Aluminum 7075-T6 and Titanium alloys. Unlike casting, machining from solid billets ensures a homogeneous grain structure, eliminating the risk of internal porosity that could lead to catastrophic failure under stress.

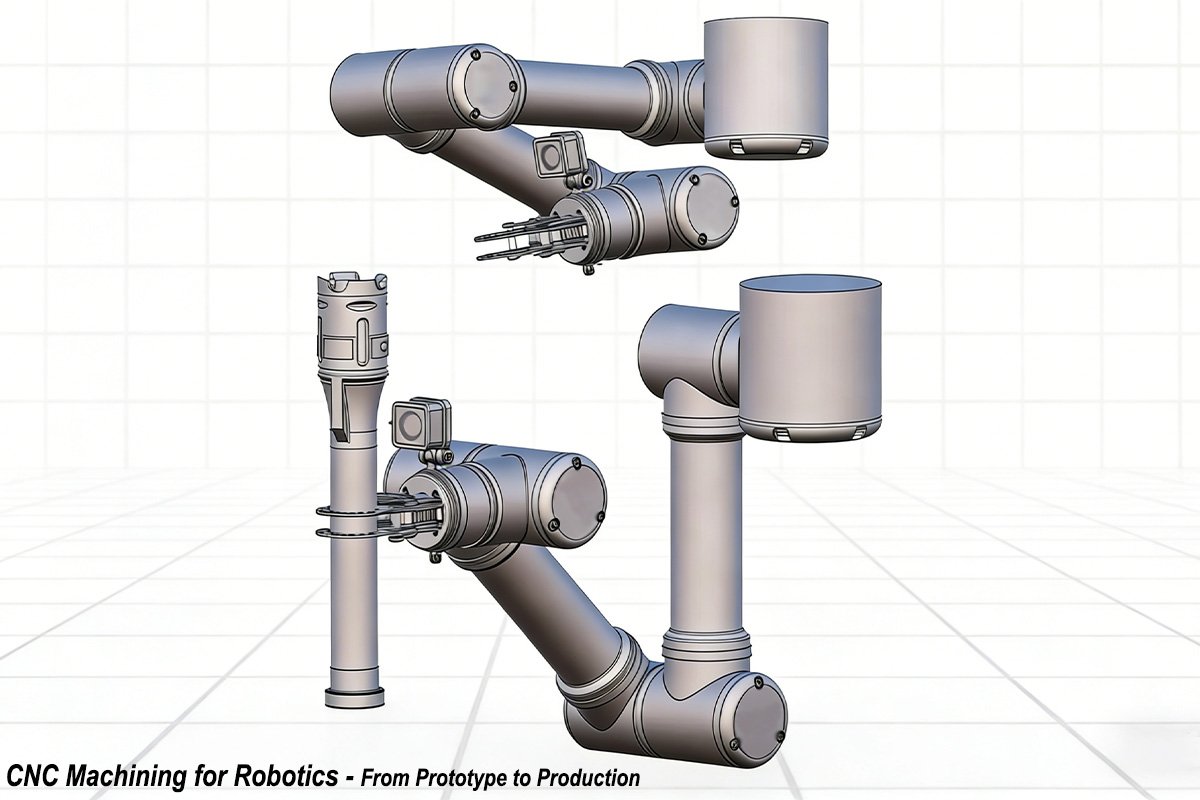

Custom CNC Machining Services for Drones and UAVs

From Rapid Prototyping to Low-Volume Production, we provide Custom CNC Machining services for Drone and UAV applications. Contact us for a free quote.

Share this article

Written by : Alex

A quick overview of the topics covered in this article.

Latest articles

March 3, 2026