Custom CNC Steel Bearing Housing

Steel bearing housings are a small but critical part of many pieces of industrial equipment—think industrial robots, automated production lines, and heavy-duty machinery. Their job is to hold bearings in place securely, support loads smoothly, and keep the whole system running without unnecessary vibration. For these machines to work reliably, the bearing housing can’t be a one-size-fits-all part.

Off-the-shelf bearing housings often fall short in real-world use. Sometimes they don’t fit the exact dimensions of your equipment; other times, the material isn’t tough enough for your working conditions. And when you do need to customize a standard part, the wait time for production can drag on, slowing down your project timeline.

That’s where Hardware Rapid’s custom CNC steel bearing housing services come in. We specialize in machining steel bearing housings that match your exact design specs, from the material grade to the smallest tolerance requirements.

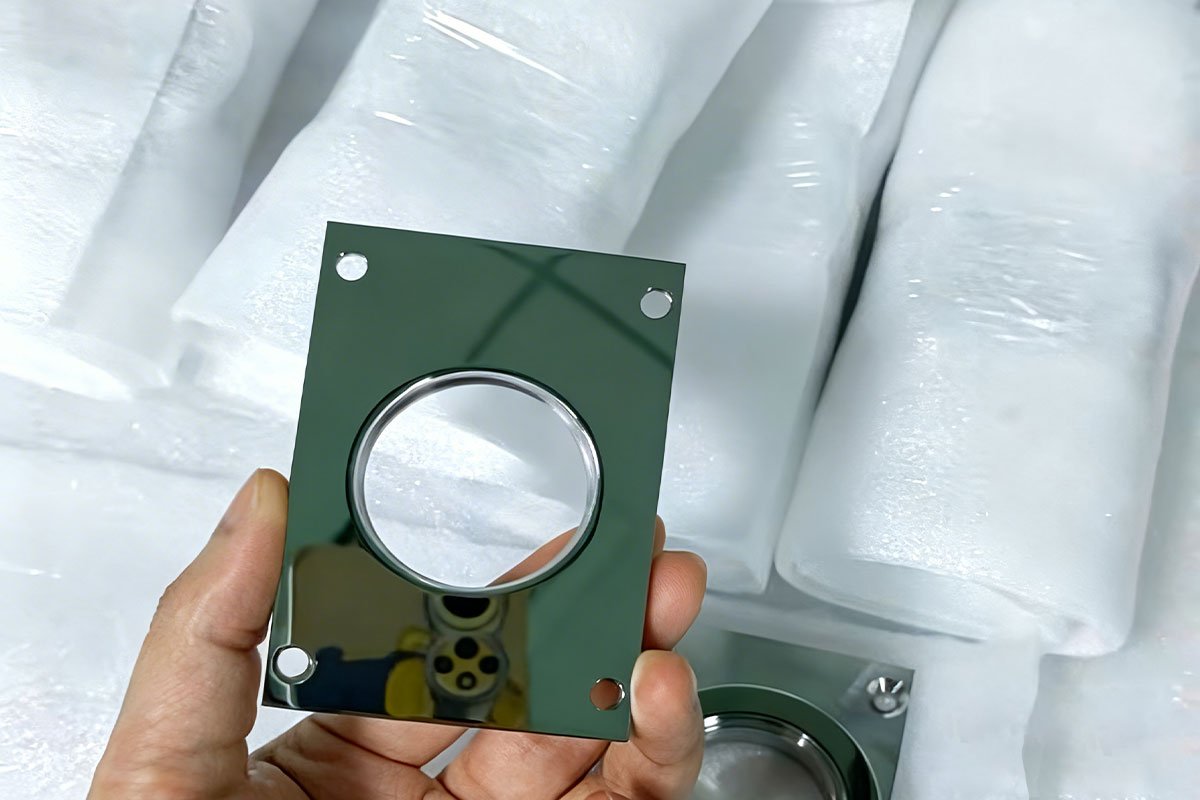

Machining Case

This is a custom bearing housing manufactured for an Australian client, crafted from C45 steel with a minimum machining tolerance of 0.1mm. Here’s how we delivered this precision component for our client:

- Material Preparation: Select bar stock in matching specifications per the bearing housing dimensions.

- CNC Rough Turning: Clamp the workpiece, turn the rough contours of the outer circle, step surfaces and inner bore, leaving a 0.5mm machining allowance.

- CNC Rough Milling: Clamp the roughly turned workpiece, mill the flat surface and side surfaces of the flange, and rough machine the mounting hole positions on the flange (leaving machining allowance for drilling).

- CNC Finish Milling: Finish mill the flange flat surface (to ensure flatness), and finish machine the mounting holes to guarantee the position tolerance of the holes.

- Deburring/Chamfering: Chamfer all sharp edges and hole openings, and remove machining burrs.

- Inspection: Use quality inspection equipment to inspect the workpiece, focusing on the inner bore diameter, flange flatness and mounting hole position, and compare the recorded inspection data with the drawing tolerances.

- On-time delivery

CNC Machining vs. Casting: Which is Right for Your Steel Bearing Housing?

When designing a custom steel bearing housing, the first question engineers often face is: Should we cast it or machine it? While casting (sand casting or investment casting) is traditionally associated with bearing housings, CNC machining has become the superior choice for high-precision, low-to-mid volume projects.

| Feature | CNC Machining | Casting |

| Setup Cost | Low (No molds required) | High (Expensive molds needed) |

| Lead Time | Fast (3-10 Days) | Slow (6-12 Weeks) |

| Precision | High (+/- 0.01mm usually) | Low (Often +/- 0.5mm+) |

| Quantity | 1 – 1,000 units | 1,000+ units |

| Design Flexibility | High (Easy to change CAD) | Low (New mold needed for changes) |

| Material Integrity | Excellent (Solid billet) | Variable (Risk of porosity) |

Choose CNC Machining if:

You need parts fast (days, not weeks).

Your volume is low to medium (1 to 1,000 parts).

You require tight tolerances for bearing fits (e.g., press fits).

You anticipate potential design changes in the future.

You need high-strength material without porosity risks.

Choose Casting if:

You are mass-producing thousands of identical housings (10,000+ per year).

Tolerances are very loose, and surface finish doesn’t matter.

Ready to Manufacture Your Custom Bearing Housing?

At Hardware Rapid, we specialize in precision CNC machining of custom bearing housings tailored to your exact specifications—from material selection to on-time global delivery.

Share this article

Written by : Alex

A quick overview of the topics covered in this article.

Latest articles

March 3, 2026