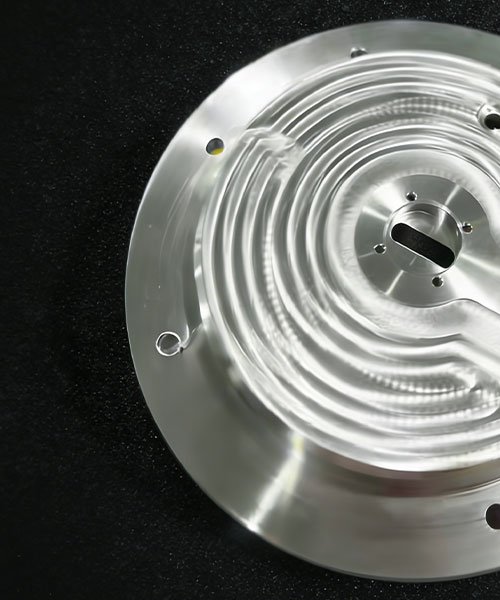

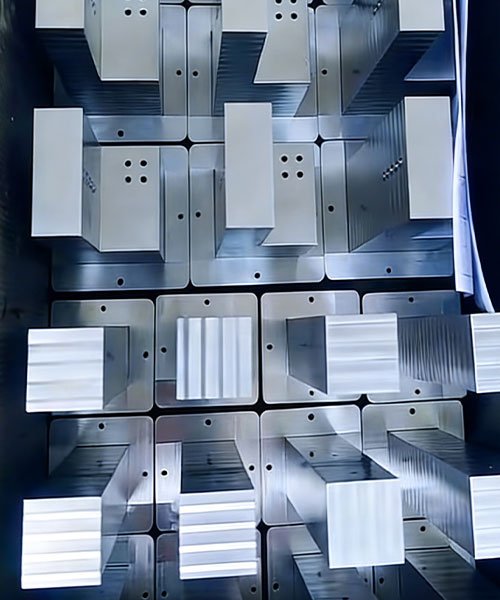

Machining stainless steel requires rigid equipment and specialized tooling strategies to overcome challenges like work hardening and high thermal generation. Our facility is equipped with high-torque CNC centers capable of holding tight tolerances on tough alloys.

Available Stainless Steel Grades

Our engineering team can assist in selecting the specific alloy that balances corrosion resistance, mechanical strength, and machinability for your application.

Stainless Steel 304 / 304L

Grade 304 is the most widely specified austenitic stainless steel. It offers excellent corrosion resistance in atmospheric and chemical environments and provides high ductility. The 304L variant has a lower carbon content, which minimizes carbide precipitation during welding, making it the standard choice for welded assemblies.

Stainless Steel 316 / 316L

316 stainless steel contains added Molybdenum (2-3%), which significantly increases its resistance to pitting and crevice corrosion, particularly in chloride-rich environments (saltwater) and acidic solutions. Like 304, the 316L grade is optimized for welding.

Stainless Steel 303

Grade 303 is modified with the addition of sulfur to improve machinability. The sulfur allows chips to break easily, allowing for faster cutting speeds and reduced tool wear compared to 304. However, the sulfur content reduces its corrosion resistance and toughness. Note: 303 is not recommended for welding.

Stainless Steel 17-4 PH

17-4 PH (AISI 630) is a martensitic precipitation-hardening stainless steel. It combines the corrosion resistance of 304 with the high tensile strength and hardness of carbon steel. Its mechanical properties can be adjusted through heat treatment (aging).

FAQs About CNC Machining Services