Titanium Grades We Machine

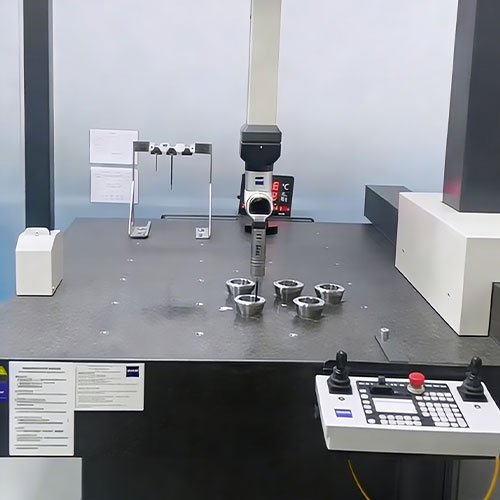

We stock Titanium raw materials in various forms, including bars, plates and tubes, to shorten lead times for both rapid prototyping and mass production. All machined parts undergo rigorous quality inspection, including CMM dimensional verification, hardness testing and biocompatibility validation, to ensure full compliance with customer design specifications and industry standards such as ASTM F136.

Ti-6Al-4V (Grade 5)

Ti-6Al-4V (Grade 5) is the most widely used titanium alloy, a two-phase alpha-beta titanium alloy formulated with 6% aluminum and 4% vanadium. It balances high mechanical performance, corrosion resistance and machinability, making it a staple material for precision custom components across industrial sectors.

This titanium grade delivers an excellent strength-to-weight ratio—far higher than steel at a fraction of the weight—while maintaining structural stability across a wide temperature range. It resists corrosion in harsh environments including saltwater, industrial chemicals and atmospheric exposure, eliminating the need for additional protective coatings in most applications.

Common applications for our custom Ti-6Al-4V (Grade 5) machined parts:

- Aerospace components (engine parts, structural connectors)

- Marine hardware (fasteners, valves)

- Automotive performance parts

- Medical device components

- Industrial precision tools

Ti-6Al-4V ELI (Grade 23)

Ti-6Al-4V ELI (Grade 23) is a low-interstitial variant of the standard Ti-6Al-4V (Grade 5) titanium alloy. As an alpha-beta titanium alloy, it maintains the excellent strength-to-weight ratio of Grade 5 while featuring lower oxygen content, which enhances its ductility, toughness and biocompatibility—making it a preferred choice for precision components requiring high reliability in critical applications.

Compared with Grade 5, Ti-6Al-4V ELI offers superior fracture toughness and fatigue resistance, especially in cryogenic and moderate temperature environments. It retains good corrosion resistance against seawater, industrial chemicals and atmospheric conditions, and its low interstitial content ensures compliance with strict biocompatibility standards. This grade is non-toxic and well-tolerated by the human body, eliminating concerns for applications involving long-term human contact.

Common applications for our custom Ti-6Al-4V ELI (Grade 23) machined parts:

- Medical implants (orthopedic implants, spinal fixation devices, dental implants)

- Marine engineering parts (deep-sea exploration equipment components, corrosion-resistant fasteners)

- High-performance industrial tools (precision molds, pressure-resistant components)

- Biomedical devices (surgical instruments, diagnostic equipment core parts)

Titanium Grade 2

Titanium Grade 2, also known as commercially pure titanium (CP), is a unalloyed titanium grade widely used in precision machining applications. As one of the most common commercially pure titanium grades, it features excellent corrosion resistance, good ductility and weldability, making it suitable for components requiring biocompatibility and reliability in mild to moderate environments.

Compared with alloyed titanium grades like Ti-6Al-4V, Titanium Grade 2 has a lower strength but superior formability and toughness. It maintains stable performance at both room temperature and moderate elevated temperatures, and exhibits outstanding resistance to corrosion from seawater, chlorine, organic acids and most industrial chemicals. Its non-toxic and biocompatible properties make it compliant with medical industry standards, requiring no additional treatment for applications involving human contact.

Common applications for our custom Titanium Grade 2 (CP) machined parts:

- Medical device components (implant accessories, surgical instruments, diagnostic equipment parts)

- Chemical processing equipment (valves, fittings, pumps, heat exchanger components)

- Marine hardware (fasteners, marine corrosion-resistant components)

- Food and beverage processing equipment (corrosion-resistant contact parts)

Performance Comparison of Common Titanium Grades

| Performance Indicator | Titanium Grade 2 (CP) | Ti-6Al-4V (Grade 5) | Ti-6Al-4V ELI (Grade 23) |

| Alloy Classification | Unalloyed (Alpha Phase) | Alpha-Beta Alloy | Alpha-Beta Alloy (Extra Low Interstitial) |

| Tensile Strength (UTS) | ≥ 345 MPa (50 ksi) | ≥ 895 MPa (130 ksi) | ≥ 860 MPa (125 ksi) |

| Yield Strength (0.2%) | ≥ 275 MPa (40 ksi) | ≥ 828 MPa (120 ksi) | ≥ 795 MPa (115 ksi) |

| Elongation (Ductility) | ≥ 20% | ≥ 10% | ≥ 10% (Typical ~15%) |

| Biocompatibility | Excellent (Dental, Maxillofacial – ASTM F67) | High (Surgical Instruments, Bone Screws – ASTM F1472) | Superior (Joint Replacements, Critical Implants – ASTM F136) |

| Corrosion Resistance | Outstanding (Best in chemical/marine environments) | Excellent (General aerospace/medical use) | Excellent (Comparable to Grade 5) |

| Fracture Toughness | High | Moderate | High (Reduced oxygen improves crack resistance) |

| Machinability | Moderate (Gummy; behaves like Stainless 316) | Difficult (Low thermal conductivity; rigid setup required) | Difficult (Similar to Gr 5; sensitive to work hardening) |

| Key Characteristic | Formability & Corrosion | Strength-to-Weight Ratio | Biocompatibility & Toughness |

Data based on ASTM B348 and ASTM F136 standards for annealed condition.

Quality Control for Custom Titanium CNC Machining

Quality control is integrated into every stage of our custom titanium CNC machining process, from raw material incoming inspection to final product delivery.

Our quality control team consists of experienced engineers and technicians with specialized knowledge of titanium alloy machining. We continuously optimize our inspection processes and update equipment to keep pace with evolving industry demands, ensuring that every custom titanium part we deliver meets or exceeds customer expectations for quality and reliability.

For projects requiring additional quality validation, we offer customized testing services, including fatigue testing, biocompatibility verification (for medical parts) and non-destructive testing (NDT), to provide further assurance for critical applications.

FAQs About CNC Machining Services