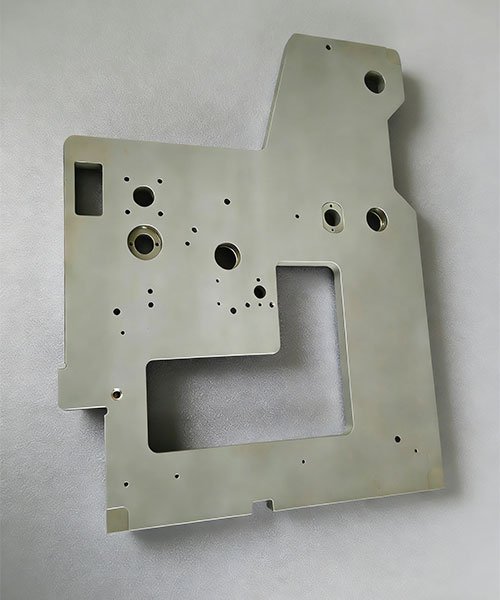

We provide precision CNC machining services for various alloy steel grades. Our capabilities include CNC milling and turning for both individual prototypes and production batches. We deliver parts according to your specified tolerances and material requirements.

AISI 4130

AISI 4130 is a chromium-molybdenum alloy structural steel with low alloy content, featuring good comprehensive performance. It is widely used in parts requiring both weldability and moderate strength, and is easy to process via conventional CNC methods.

AISI 4140

AISI 4140 is a chromium-molybdenum alloy structural steel with excellent comprehensive mechanical properties. It is a universal alloy steel widely used in precision mechanical parts, featuring adjustable performance through quenching and tempering.

AISI 4340

AISI 4340 is a nickel-chromium-molybdenum alloy structural steel with higher alloy content than 4140. It offers superior mechanical properties, making it ideal for high-load and critical structural components.

AISI 8620

AISI 8620 is a nickel-chromium-molybdenum alloy structural steel with excellent carburizing performance. It is commonly used in transmission parts requiring high surface hardness and tough core.

AISI 52100

AISI 52100 is a high-carbon chromium alloy bearing steel, a subcategory of alloy structural steel. It is characterized by high hardness and wear resistance, suitable for wear-resistant and precision parts.

FAQs About CNC Machining Services