Surface Finishing Services

Tailored to your specs, our services boost part performance, corrosion resistance, and aesthetic appeal. Fast turnaround, strict quality checks, and perfect fits for automotive, aerospace, and industrial applications.

Let’s make your parts look and work their best.

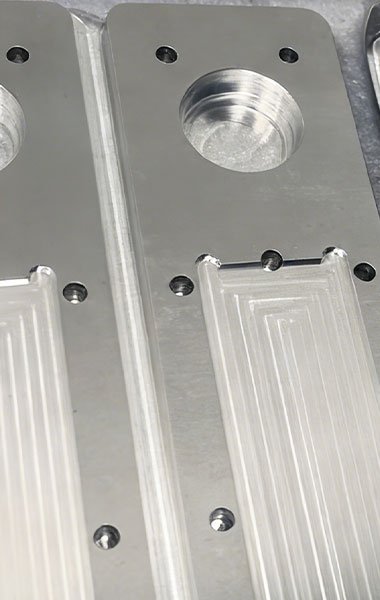

The most cost-effective and fastest finishing option. Parts are delivered straight from the CNC machine with visible tool marks. This finish creates no dimensional changes, making it the best choice for tight-tolerance features and mating surfaces.

The most cost-effective and fastest finishing option. Parts are delivered straight from the CNC machine with visible tool marks. This finish creates no dimensional changes, making it the best choice for tight-tolerance features and mating surfaces.

We ensure all parts are deburred, sharp edges are broken (chamfered), and the surface is cleaned of all oil and coolant.

Technical Specs

Surface Roughness (Ra): Standard Ra 3.2μm (125μin). Can be improved to Ra 1.6μm or Ra 0.8μm with fine finishing passes upon request.

Dimensional Change: 0mm (No coating thickness added).

Visual Appearance: Visible swirl marks from milling tools. Bright/Shiny for Aluminum/Steel; Matte for plastics.

Pros & Cons

Pros: Lowest cost, Fastest delivery, Tightest tolerances.

Cons: Visible tool marks, Lower corrosion resistance (unless material is stainless/plastic), Prone to fingerprints.

The industry standard for finishing aluminum. Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, and decorative anodic oxide finish. Unlike paint, this finish is integrated with the underlying aluminum, so it will not chip or peel. We match Pantone or RAL codes.

The industry standard for finishing aluminum. Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, and decorative anodic oxide finish. Unlike paint, this finish is integrated with the underlying aluminum, so it will not chip or peel. We match Pantone or RAL codes.

Type II (Standard / Sulfuric Anodizing):

Best for: Cosmetics & Corrosion resistance.

Colors: Available in virtually any color (Black, Red, Blue, Gold, Clear).

Thickness: Adds ~5-25μm (.0002″-.001″).

Type III (Hardcoat Anodizing):

Best for: Extreme wear resistance & Hardness (Harder than tool steel!).

Colors: Usually limited to Dark Grey or Black (due to coating density).

Thickness: Adds ~25-50μm (.001″-.002″).

Conductive Film (Alodine / Chem Film):

Note: Anodizing is non-conductive (electrically insulating). If you need grounding, we offer Alodine coating or selective masking.

The secret to a uniform, premium finish. Bead blasting bombards the part surface with glass beads or ceramic media to remove visible CNC tool marks and minor burrs. It creates a smooth, non-reflective “Satin” or “Matte” texture. This is the standard preparation step before Anodizing to ensure a flawless, consistent cosmetic appearance.

The secret to a uniform, premium finish. Bead blasting bombards the part surface with glass beads or ceramic media to remove visible CNC tool marks and minor burrs. It creates a smooth, non-reflective “Satin” or “Matte” texture. This is the standard preparation step before Anodizing to ensure a flawless, consistent cosmetic appearance.

Glass Beads: The most common media. Cleans and polishes without removing too much material. Leaves a bright, satin finish.

Aluminum Oxide: More aggressive. Used for etching the surface to improve adhesion before Powder Coating or painting.

Grit Size Options:

#120 (Fine): Smooth, velvety finish. (Standard for high-end electronics).

#80 (Medium): Slightly rougher texture. Better at hiding surface defects.

#60 (Coarse): Heavy texture. Good for non-slip surfaces.

Pros: Hides machining marks, removes light burrs, improves coating adhesion, uniform look.

Cons: Not suitable for tight tolerance surfaces (removes ~0.01mm), prone to fingerprints if left uncoated (must be anodized/coated after).

Whether you need a rugged “armor” for outdoor machinery or a high-gloss “automotive” finish for consumer electronics, XINGDA covers it all. Unlike anodizing, coating can be applied to Steel, Magnesium, and Plastics, offering complete protection against corrosion and UV rays. We utilize professional Masking (Plugging/Capping) techniques to ensure paint only goes where you want it, keeping threads and grounding points clean.

Whether you need a rugged “armor” for outdoor machinery or a high-gloss “automotive” finish for consumer electronics, XINGDA covers it all. Unlike anodizing, coating can be applied to Steel, Magnesium, and Plastics, offering complete protection against corrosion and UV rays. We utilize professional Masking (Plugging/Capping) techniques to ensure paint only goes where you want it, keeping threads and grounding points clean.

We match: RAL (Standard for Powder Coating) and Pantone (PMS) (Standard for Wet Painting).

Gloss Levels: Flat (Matte), Satin, Semi-Gloss, High-Gloss.

Powder Coating

The “Industrial Armor”. Dry powder is electrostatically sprayed and cured under heat.

Best For: Aluminum/Steel brackets, Enclosures, Outdoor equipment, Heavy machinery.

Pros: Extremely durable, chip-resistant, eco-friendly (No VOCs), hides surface scratches well.

Texture: Glossy, Matte, Sand-texture (Sandtex), Wrinkle finish.

Wet Painting / Spray Painting:

The “Cosmetic Artist”. Liquid paint applied via spray guns.

Best For: Plastic Prototypes (ABS/PC), Magnesium parts, High-gloss automotive parts.

Specialty Options:

Soft-Touch Paint: Rubberized feel (like a mouse or remote control).

High-Gloss (Piano Black): Mirror-like finish.

EMI/RFI Shielding: Conductive copper/nickel paint for inside plastic housings.

The ultimate shield for metals. Plating deposits a thin layer of metal onto the substrate to enhance its properties. Whether you need Zinc to prevent steel from rusting, Electroless Nickel for uniform hardness, or Gold for electrical conductivity, XINGDA manages the entire process. Compliance Note: All our plating services are RoHS / REACH compliant, ensuring your parts meet international environmental standards.

The ultimate shield for metals. Plating deposits a thin layer of metal onto the substrate to enhance its properties. Whether you need Zinc to prevent steel from rusting, Electroless Nickel for uniform hardness, or Gold for electrical conductivity, XINGDA manages the entire process. Compliance Note: All our plating services are RoHS / REACH compliant, ensuring your parts meet international environmental standards.

We match: RAL (Standard for Powder Coating) and Pantone (PMS) (Standard for Wet Painting).

Gloss Levels: Flat (Matte), Satin, Semi-Gloss, High-Gloss.

Zinc Plating :

Best For: Low-cost rust protection for Steel and Iron.

Colors: Blue-Zinc (Silver look), Yellow-Zinc (Rainbow/Gold look), Black-Zinc.

Nickel Plating:

Electrolytic Nickel: Bright, shiny finish. Good for decoration.

Electroless Nickel: Does not use electricity. Plates evenly on all surfaces (even inside deep holes). High hardness and wear resistance. Ideal for precision shafts and gears.

Chrome Plating:

Hard Chrome: Thick, industrial coating for extreme wear resistance (e.g., Hydraulic rods).

Decorative Chrome: Thin, mirror-like finish (e.g., Motorcycle parts, Bathroom fittings).

The finishing touch that defines your product. Whether you need a permanent serial number for tracking or a vibrant multi-color logo for branding, XINGDA offers high-definition marking solutions.

The finishing touch that defines your product. Whether you need a permanent serial number for tracking or a vibrant multi-color logo for branding, XINGDA offers high-definition marking solutions.

Laser Engraving / Etching:

The “Permanent” Choice. A high-powered laser beam removes material or surface coating.

Best For: Serial numbers, Barcodes/QR codes, Logos on metal.

Visual Effect: On Anodized Aluminum, the laser burns off the colored layer to reveal the silver metal underneath (High Contrast). On Stainless Steel, it can create a dark annealed mark.

Pros: Permanent (cannot be scratched off), fast, no ink needed.

Silk Screening / Pad Printing:

The “Colorful” Choice. Ink is applied through a mesh screen onto the part.

Best For: Branding logos with specific colors (Pantone matching), Warning labels, Button text on plastic panels.

Pros: Can print in ANY color (Red, White, Yellow, etc.).

Cons: Not as durable as laser; ink can wear off over time without a protective clear coat.

Note: Vector Files Required: Please provide .AI, .EPS, or .DXF files.

(Raster images like .JPG or .PNG are difficult to process for crisp edges.

For text smaller than 2mm height, always choose Laser Engraving. Silk screening ink has viscosity limits and can smudge or blur on tiny text, whereas lasers offer micron-level precision.