About Us

Based in Hong Kong, XINGDA CNC LIMITED specializes in high-quality CNC machining services for the global market.

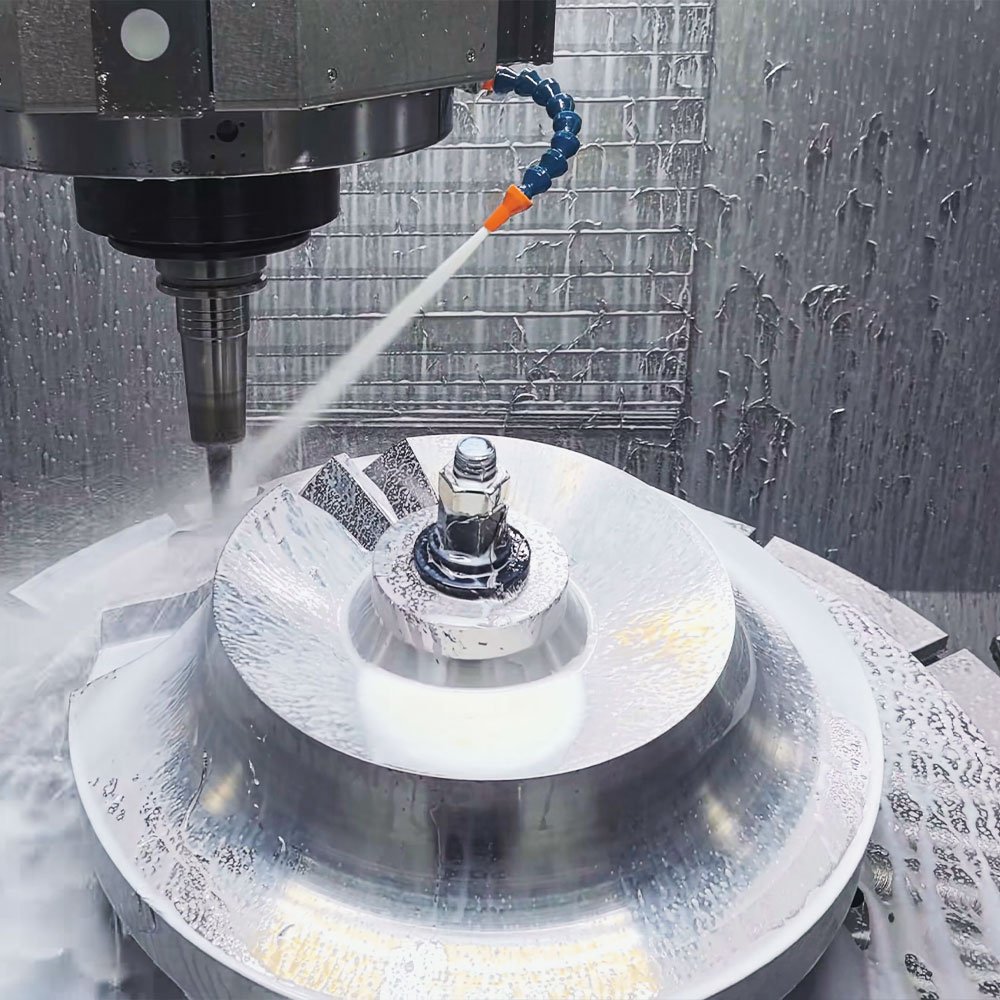

We specialize in turning your design concepts into high-precision, quality parts — from prototyping to low and high-volume production runs. Our team leverages advanced CNC milling, turning, and finishing technologies to meet the strictest tolerances and specifications across industries like automotive, electronics, aerospace, and industrial equipment.

At XINGDA CNC, we prioritize reliability, efficiency, and customer-centricity. Every project is handled with meticulous attention to detail, and we work closely with you from quote to delivery to ensure your exact requirements are met — on time and within budget.

One-Stop CNC Machining Services

From design optimization, material selection, precision CNC milling/turning to surface finishing and quality inspection—we handle it all. Custom solutions for your industrial equipment parts, delivered on time, every time.

10,000+ Successful Projects

Our one-stop CNC machining solutions meet diverse industrial needs—on time, with precision.

120k+

Parts Delivered

99%

On Time, In Spec

Some of XINGDA CNC LIMITED’s In-House Quality Control Equipment: Strict QC Process

Our shop has all the quality control gear we need to deliver perfect CNC parts.

Our in-house tools let us inspect every piece before it leaves our door—so you never have to worry about quality issues.

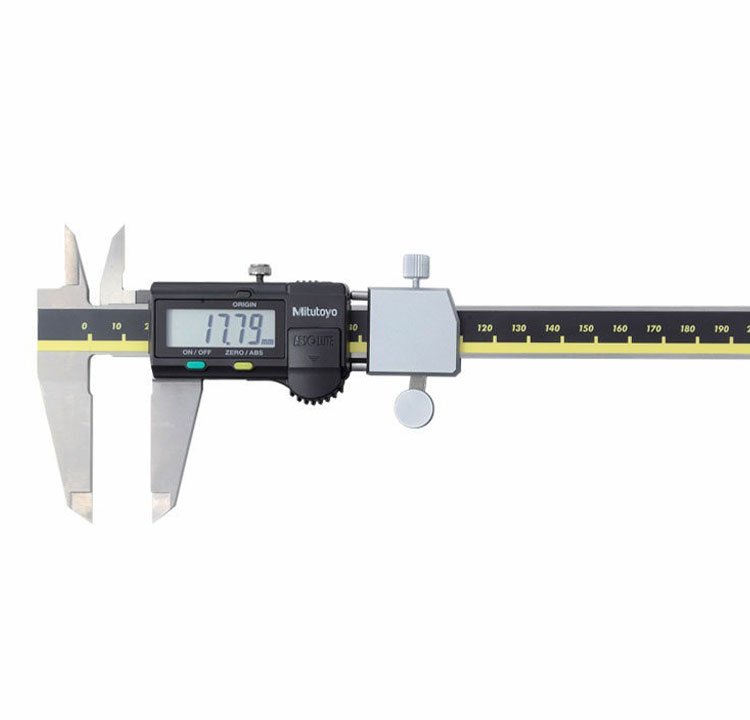

Mitutoyo Calipers: Your Go-To for Quick, Precise Checks

Another workhorse in our in-house QC toolkit: Mitutoyo digital calipers. These handy tools let our team take fast, accurate measurements.

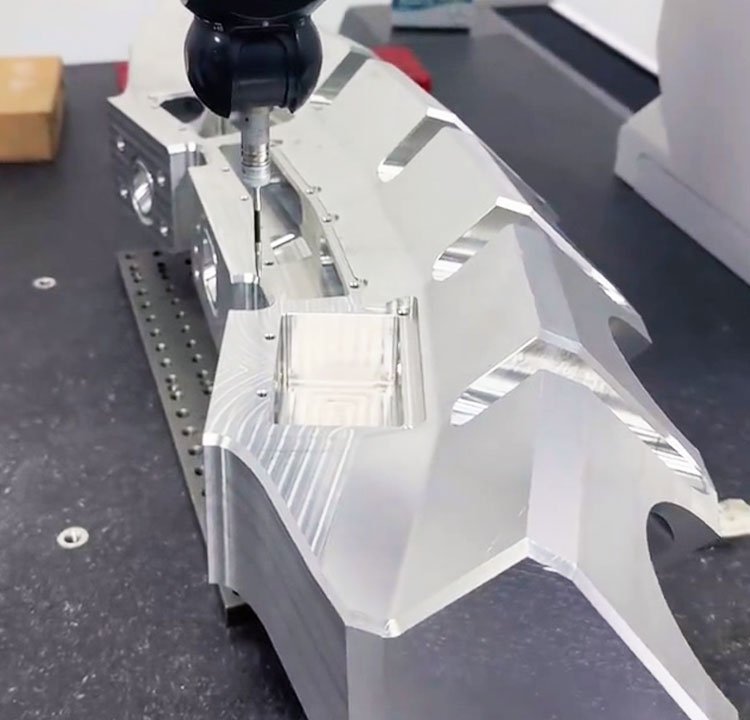

Our CMM (Coordinate Measuring Machine)

It checks every nook and cranny of your machined parts—holes, curves, tiny tolerances, you name it.

Vickers Hardness Tester

It works by pressing a tiny diamond indenter into the part’s surface, then calculating hardness based on the indentation size. Perfect for making sure heat-treated or finished parts meet your material strength standards.